Cam timing

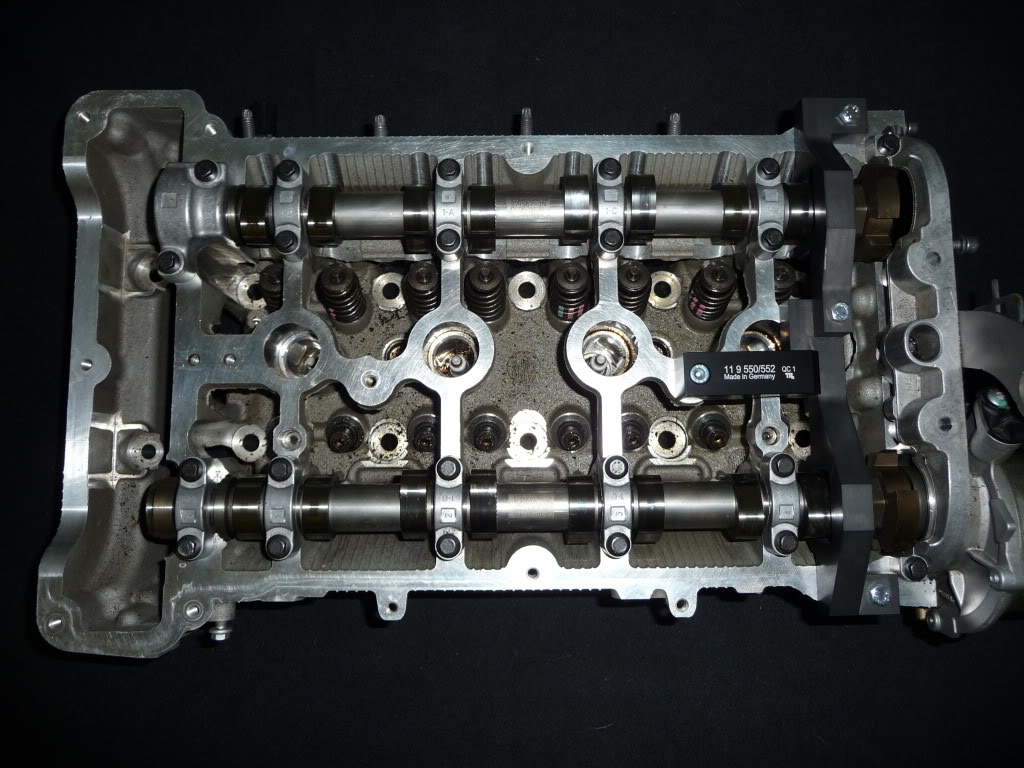

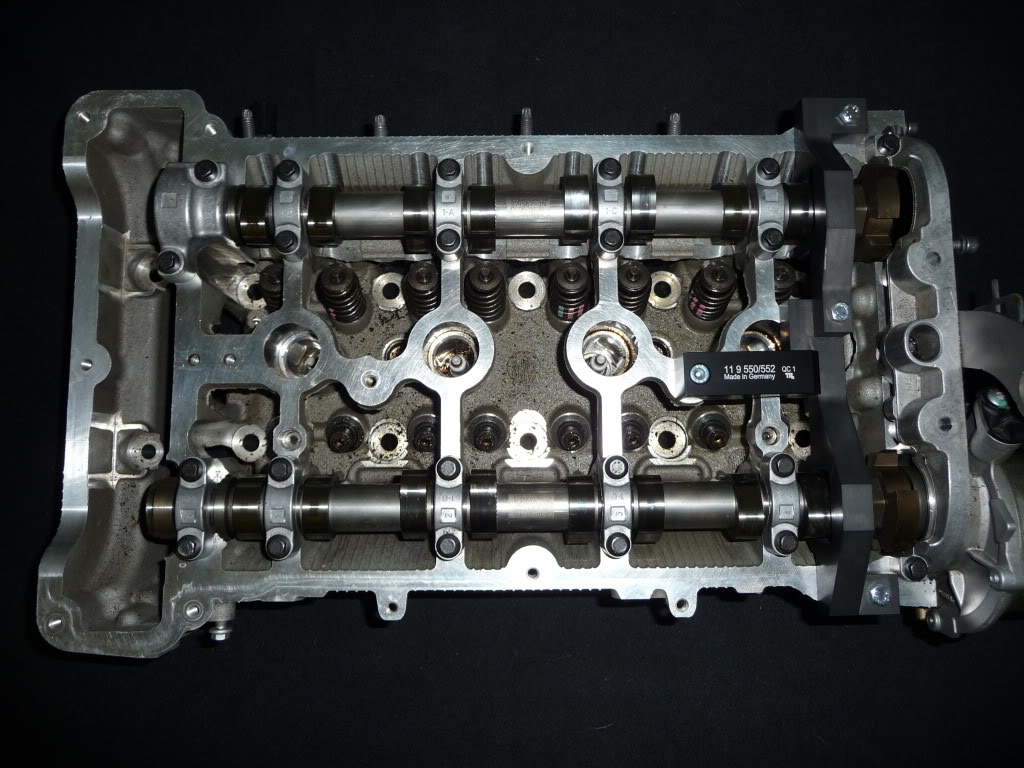

#2

you cannot time the engine at TDC, there are no timing marks on the N14 engine!

You must lock the crankshaft at 90 degrees BTDC first, and then the camshafts must be locked in their relative position, to make sure the cams are in their relative position, you will see the index writing face upwards, between No 2 and No 3 lobes on both the Inlet and Exhaust camshafts.

Do NOT attempt to to set your camshaft/crankshaft timing up, without the correct locking tools, as it will end in tears!

You must lock the crankshaft at 90 degrees BTDC first, and then the camshafts must be locked in their relative position, to make sure the cams are in their relative position, you will see the index writing face upwards, between No 2 and No 3 lobes on both the Inlet and Exhaust camshafts.

Do NOT attempt to to set your camshaft/crankshaft timing up, without the correct locking tools, as it will end in tears!

#3

#4

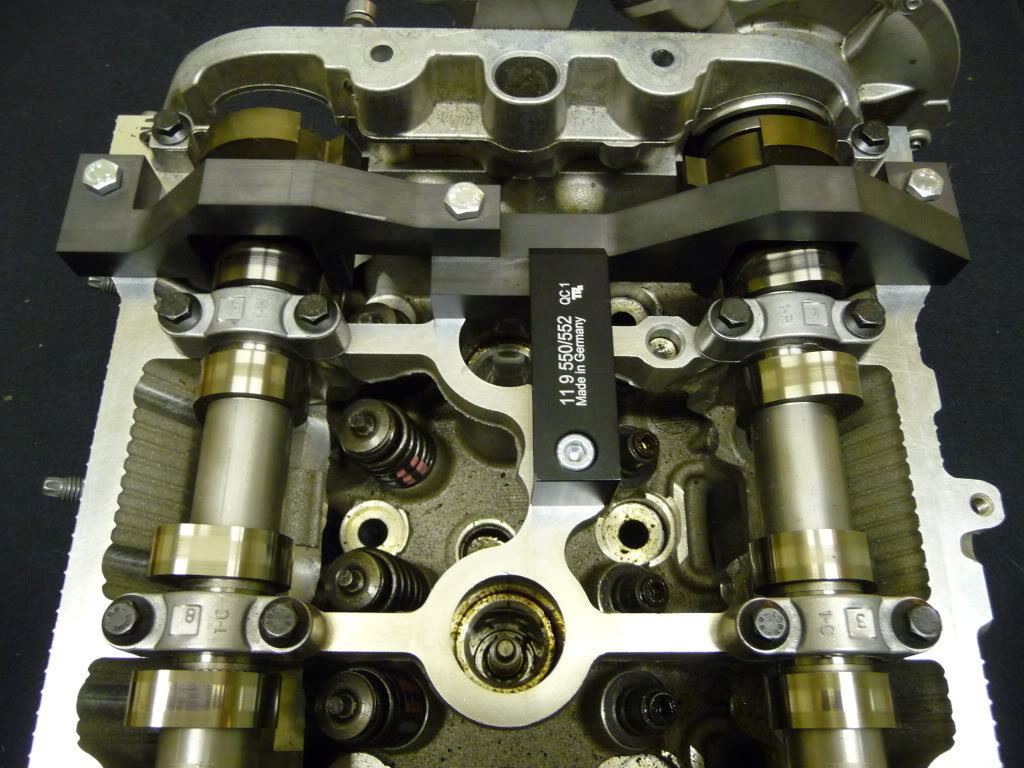

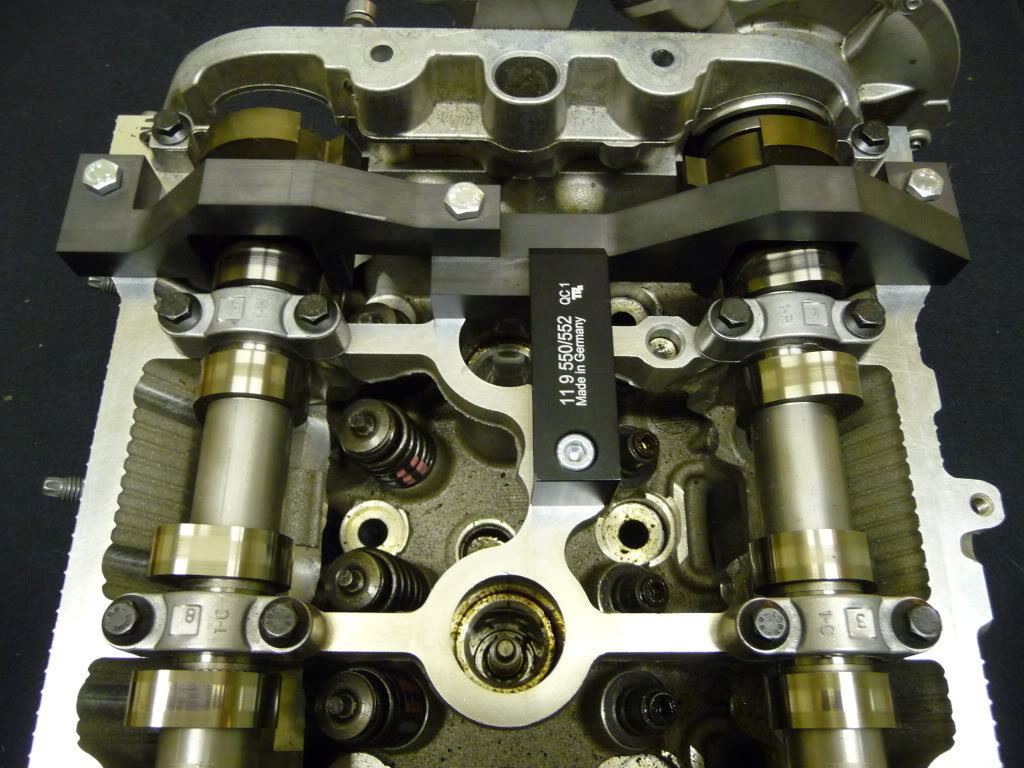

If you take a good look at this photo, you can just make out the index writing on both camshafts (centre of picture) whilst the camshafts are locked in their correct positions (index writing must always be upward facing) it is possible to lock the camshafts 180 degree out of time (index writing downward facing) and this is WRONG, so be very careful.

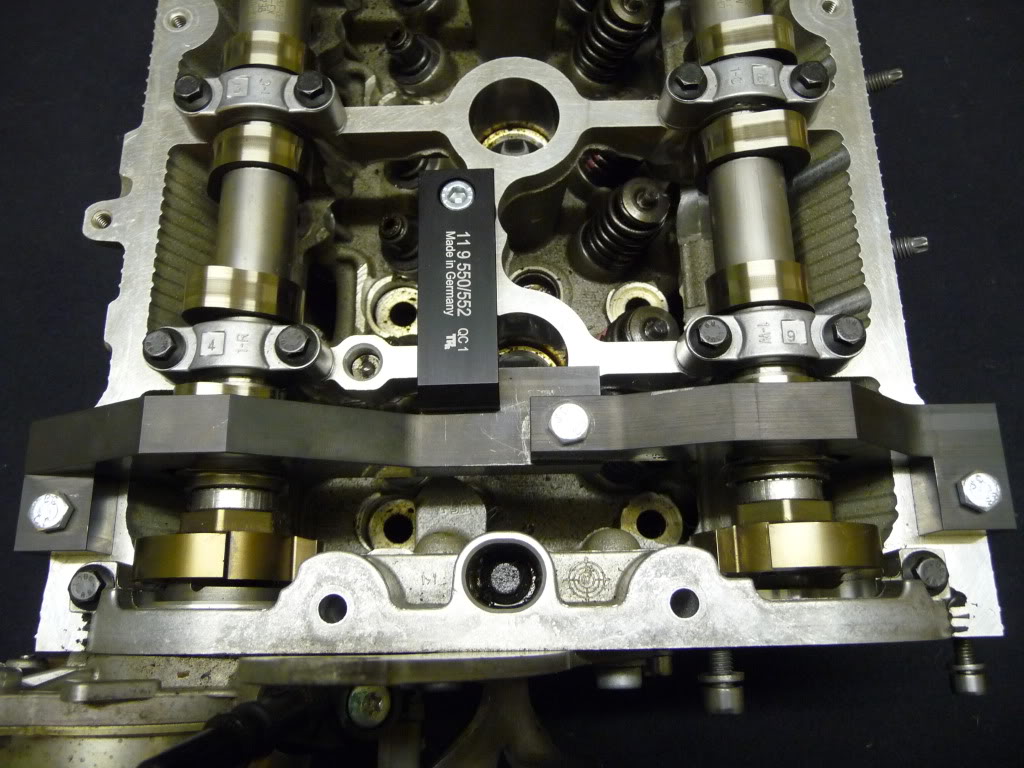

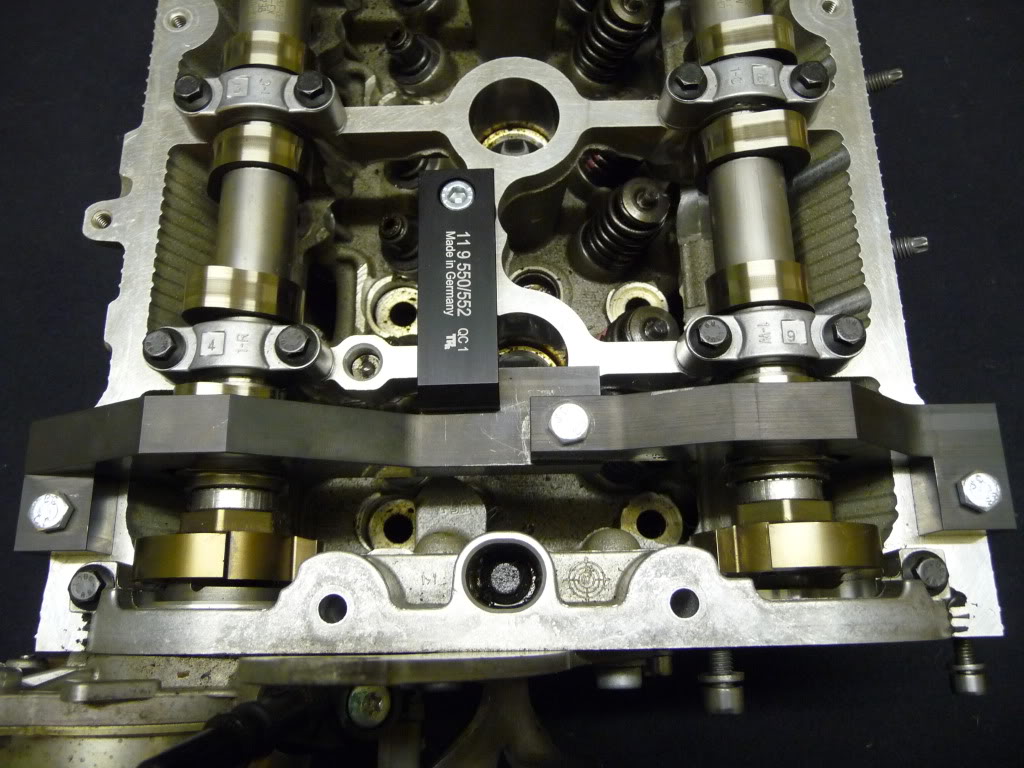

Another view of the camshafts correctly locked in position.

In this photo you can just see the index writing on the Exhaust camshaft (top left of picture) with the camshafts locked in their correct positions.

Crankshaft locking pin.

Camshafts locking tool

Another view of the camshafts correctly locked in position.

In this photo you can just see the index writing on the Exhaust camshaft (top left of picture) with the camshafts locked in their correct positions.

Crankshaft locking pin.

Camshafts locking tool

#5

#7

i have a peugeot 207gti which has the same engine as the mini, and i had this same problem with the camshaft timing, this problem has happened to quite a few of us with peugeots, your camshafts look out of timing to me, both of my camshafts were out of timing, but when i bought a new ported and polished cylinder head from czar, he fitted my camshafts for me to my new cylinder head which came with the camshaft locking tool in place like in his pictures, it was an option to either purchase the tool with the cost of the cylinder head or return it to him after i fitted the cylinder head and he would refund my deposit for the tool i returned to him, i found it easy to do the job with help from czar.

Trending Topics

#8

Remember when you re-build your timing issues, you MUST renew the camshaft sprocket bolts, the applied torque of 20Nm (14.75 lb-ft) + 180 degree of torque angle must be applied to the Inlet vanos sprocket, and is all that keeps the sprocket clamped and aligned to the inlet camshaft, the sprockets do NOT have assistance from key ways (this applies to the crankshaft sprocket/s too!)

The tightening torque for the exhaust camshaft sprocket bolt is: 20Nm (14.75 lb-ft) + 90 degrees of torque angle.

#9

i have a peugeot 207gti which has the same engine as the mini, and i had this same problem with the camshaft timing, this problem has happened to quite a few of us with peugeots, your camshafts look out of timing to me, both of my camshafts were out of timing, but when i bought a new ported and polished cylinder head from czar, he fitted my camshafts for me to my new cylinder head which came with the camshaft locking tool in place like in his pictures, it was an option to either purchase the tool with the cost of the cylinder head or return it to him after i fitted the cylinder head and he would refund my deposit for the tool i returned to him, i found it easy to do the job with help from czar.

#10

Thanks so much czar. To be honest I don't like the design, I had rather have the key ways but what do I know.

I made a separate post but was wondering how to set the crank at 90 BTD so I can see which or if both cams are in alignment. I looked for a way to lock the crank but did not see one. I was thinking it would be like my Boxster where you can put a pin through the sprocket into the block. If you have time and could describe the proper method I would appreciate it. Thanks.

I made a separate post but was wondering how to set the crank at 90 BTD so I can see which or if both cams are in alignment. I looked for a way to lock the crank but did not see one. I was thinking it would be like my Boxster where you can put a pin through the sprocket into the block. If you have time and could describe the proper method I would appreciate it. Thanks.

#11

The crankshaft locking pin is inserted into the back of the flywheel, looking from the front of the vehicle at the underside of the engine, on the right hand side (gearbox side) of the exhaust downpipe, you will see a hole in the Aluminium crankshaft cradle half moon, there is only 1 hole in the back of the flywheel, so simply place locking pin through the designated hole, rotate crankshaft until the locking pin finds its holed position, this will now be 90 degrees BTDC (all pistons level at mid point)

#12

#13

#15

You can either get them from your local BMW Mini dealer, or you can get them from Koch tools, click link below.

http://www.kochtools.com/index.php?p...parent=14&pg=1

http://www.kochtools.com/index.php?p...parent=14&pg=1

#17

08 clubman timing cam position

hey fellas i have a 08 mini clubman and had to remove cylinder head, i have aligment tools the only thing that im stuck is the process on how to align the cam sprockets, can anybody please give me some idea of post images. this car is driving me nuts. help anyone?

#18

There is no alignment for either the inlet or exhaust cam sprockets, providing you have locked the crankshaft at 90 degree BTDC, and the camshafts in their relevant positions, then the chain and sprockets, can be installed in any position!

You will notice there are no key way location pegs, hence the sprockets can be fit in any position, also you MUST fit new retaining bolts in both camshaft sprockets, this is very very important, as is the correct retaining torque for the sprocket bolts.

The crankshaft sprocket is the same, this has no key way location peg, and can be fit in any position, it relies on a central bolt with the correct torque value applied, again this bolt MUST be replaced if you ever loosen it!

Inlet vanos sprocket bolt tightening torque: 20NM + 180 degree tightening torque angle

Exhaust sprocket bolt tightening torque: 20NM + 90 degree tightening torque angle

Crankshaft central retaining bolt tightening torque: 50NM + 100 degree tightening torque angle

You will notice there are no key way location pegs, hence the sprockets can be fit in any position, also you MUST fit new retaining bolts in both camshaft sprockets, this is very very important, as is the correct retaining torque for the sprocket bolts.

The crankshaft sprocket is the same, this has no key way location peg, and can be fit in any position, it relies on a central bolt with the correct torque value applied, again this bolt MUST be replaced if you ever loosen it!

Inlet vanos sprocket bolt tightening torque: 20NM + 180 degree tightening torque angle

Exhaust sprocket bolt tightening torque: 20NM + 90 degree tightening torque angle

Crankshaft central retaining bolt tightening torque: 50NM + 100 degree tightening torque angle

Last edited by czar; 08-09-2011 at 03:12 AM.

#21

That said, it's very very straight forward, as I've already mentioned, providing you've locked the crankshaft and camshafts in their relative correct positions, I say correct, as you can lock the camshafts 180 degrees out!

Then it's plain sailing all the way to job completion, the only tool you won't have is, the tool to replicate the chain tensioner, this is screwed in, in place of the chain tensioner, and preloads the chain and holds the chain steady, whilst you tighten the sprockets.

The reason for this tool is, to ensure correct chain preload and inlet vanos sprocket preload!

Without this tool, just be careful when tightening your sprocket bolts, that all the chain slack remains on the chain tensioner side, because you are now tightening against the spring preload pressure of the chain tensioner itself!

#22

I can't help you with an image step by step, surely if you've stripped it down, then it's a reverse procedure of everything you've done!

That said, it's very very straight forward, as I've already mentioned, providing you've locked the crankshaft and camshafts in their relative correct positions, I say correct, as you can lock the camshafts 180 degrees out!

Then it's plain sailing all the way to job completion, the only tool you won't have is, the tool to replicate the chain tensioner, this is screwed in, in place of the chain tensioner, and preloads the chain and holds the chain steady, whilst you tighten the sprockets.

The reason for this tool is, to ensure correct chain preload and inlet vanos sprocket preload!

Without this tool, just be careful when tightening your sprocket bolts, that all the chain slack remains on the chain tensioner side, because you are now tightening against the spring preload pressure of the chain tensioner itself!

That said, it's very very straight forward, as I've already mentioned, providing you've locked the crankshaft and camshafts in their relative correct positions, I say correct, as you can lock the camshafts 180 degrees out!

Then it's plain sailing all the way to job completion, the only tool you won't have is, the tool to replicate the chain tensioner, this is screwed in, in place of the chain tensioner, and preloads the chain and holds the chain steady, whilst you tighten the sprockets.

The reason for this tool is, to ensure correct chain preload and inlet vanos sprocket preload!

Without this tool, just be careful when tightening your sprocket bolts, that all the chain slack remains on the chain tensioner side, because you are now tightening against the spring preload pressure of the chain tensioner itself!

#23

The camshaft sprockets although they are both attached to camshafts, that's where the similarities end, they do not do the same job, the inlet vanos unit is a constantly variable moving sprocket, and the hydraulic centrifugal forces which operate the vanos unit sprocket, put heavy loadings on the central retaining bolt, and this requires a greater tightening applied torque, when compared to the static operation of the exhaust camshaft sprocket.

The tightening torque values, I have supplied to you, are for all MCS and JCW N14 engines, and NOT the N12.

The tightening torque values, I have supplied to you, are for all MCS and JCW N14 engines, and NOT the N12.

#25

Guys I am in desperate help here. I have R56 2008 base model MINI. The Crank Shaft Seal was dripping oil. So I decided to replace it by pulling out the Hub. Of course maybe I should have done it by installing seal over the Hub, but was afraid that it would not do any good to new seal. Man I wish I knew that, removing the Bolt would mess up the timing of Crankshaft to CamShafts. By loosing the Crankshaft bolt I believe timing went off just by little. In my case, I should do the same, by getting the Crankshaft in BTDS with 90 Degree set up and then lock the camshafts with that special tool relevant to Crankshaft and then use the 50NM+100 Degree torque tightening the new sprocket bolt of crankshaft? Please HELP...?