Air conditioner troubleshooting help

#1

Air conditioner troubleshooting help

2013 Mini R56, IHKS, manual AC system. It suddenly stopped blowing cold air a month or so ago. I took it to a reliable shop, but one that does not have mini diagnostics equipment. So far they have replaced compressor, Evap valve, temperature sensor, and flushed the system several times; it still doesnít work. Reasonably good low and high pressure readings. Theyíve given up, saying (with a laugh, not seriously) that the car is defying physics: cold air should be blowing out.

So - Iím trying to do a bit of troubleshooting on my own. First off - is it worth it for me to get a scan tool of some sort do diagnose the IHKS? I hate to for this one project, and I havenít found a lot of info on just what I can see/test through the software. That said, I have nothing to go by to figure out what sensor is doing what, when - Bentley is useless in this case. Second, has anyone had similar issues and found a solution?

Thanks. Iíll post more data as i go today.

So - Iím trying to do a bit of troubleshooting on my own. First off - is it worth it for me to get a scan tool of some sort do diagnose the IHKS? I hate to for this one project, and I havenít found a lot of info on just what I can see/test through the software. That said, I have nothing to go by to figure out what sensor is doing what, when - Bentley is useless in this case. Second, has anyone had similar issues and found a solution?

Thanks. Iíll post more data as i go today.

#3

Did they check if the heater is fully closed when you put the thermostat on max cold? If not then youíre reheating the cold air. An easy check to see if your AC system is working touch the suction pipe going into the evaporator at the firewall. Thatís the larger diameter pipe leaving the compressor. It should be freezing cold. If itís not then thereís something going on with your system. Are the condenser fans engaging correctly?

#4

#5

Just reread your initial post. So they havenít replaced the AC receiver drier?! This is mandatory whenever your changing compressor/evaporator valve! If your system is clogged you need to change the drier. I think the only downside for this in the mini the drier is integrated with the condenser. So that means you need to change the condenser itself.

#6

A little history:

- December - installed a new engine (long story) at this time I installed new receiver/dryer/condenser. Brought to shop that vacuumed/filled the system, ac worked fine

- may - ac stopped blowing cold. Had same shop drain/refill, they suspected evap valve. Drained/replaced evap valve. System worked for a day or two then failed

- late May - replaced pressure switch, no changes.

- early June - replaced condenser with Chinese Amazon one. It did weird things - pressure would spike,then drop to nothing, spike, then drop to nothing...replaced with used Mini compressor.

Every time the system has been apart it has been sealed when open and/or only open for short time periods in low humidity weather. And every time it has been recharges it has been vacuumed/recharged with commercial service equipment by trained (non-mini) mechanics. I agree that, technically, the dryer should be being replaced every time, but I don’t think this sounds like a moisture issue

I’m increasingly suspecting electronics. I checked the condenser thermocouple inside the car today and it’s spot on, Im now going through all the connections/grounds.

- December - installed a new engine (long story) at this time I installed new receiver/dryer/condenser. Brought to shop that vacuumed/filled the system, ac worked fine

- may - ac stopped blowing cold. Had same shop drain/refill, they suspected evap valve. Drained/replaced evap valve. System worked for a day or two then failed

- late May - replaced pressure switch, no changes.

- early June - replaced condenser with Chinese Amazon one. It did weird things - pressure would spike,then drop to nothing, spike, then drop to nothing...replaced with used Mini compressor.

Every time the system has been apart it has been sealed when open and/or only open for short time periods in low humidity weather. And every time it has been recharges it has been vacuumed/recharged with commercial service equipment by trained (non-mini) mechanics. I agree that, technically, the dryer should be being replaced every time, but I don’t think this sounds like a moisture issue

I’m increasingly suspecting electronics. I checked the condenser thermocouple inside the car today and it’s spot on, Im now going through all the connections/grounds.

#7

A little history:

- December - installed a new engine (long story) at this time I installed new receiver/dryer/condenser. Brought to shop that vacuumed/filled the system, ac worked fine

- may - ac stopped blowing cold. Had same shop drain/refill, they suspected evap valve. Drained/replaced evap valve. System worked for a day or two then failed

- late May - replaced pressure switch, no changes.

- early June - replaced condenser with Chinese Amazon one. It did weird things - pressure would spike,then drop to nothing, spike, then drop to nothing...replaced with used Mini compressor.

Every time the system has been apart it has been sealed when open and/or only open for short time periods in low humidity weather. And every time it has been recharges it has been vacuumed/recharged with commercial service equipment by trained (non-mini) mechanics. I agree that, technically, the dryer should be being replaced every time, but I donít think this sounds like a moisture issue

Iím increasingly suspecting electronics. I checked the condenser thermocouple inside the car today and itís spot on, Im now going through all the connections/grounds.

- December - installed a new engine (long story) at this time I installed new receiver/dryer/condenser. Brought to shop that vacuumed/filled the system, ac worked fine

- may - ac stopped blowing cold. Had same shop drain/refill, they suspected evap valve. Drained/replaced evap valve. System worked for a day or two then failed

- late May - replaced pressure switch, no changes.

- early June - replaced condenser with Chinese Amazon one. It did weird things - pressure would spike,then drop to nothing, spike, then drop to nothing...replaced with used Mini compressor.

Every time the system has been apart it has been sealed when open and/or only open for short time periods in low humidity weather. And every time it has been recharges it has been vacuumed/recharged with commercial service equipment by trained (non-mini) mechanics. I agree that, technically, the dryer should be being replaced every time, but I donít think this sounds like a moisture issue

Iím increasingly suspecting electronics. I checked the condenser thermocouple inside the car today and itís spot on, Im now going through all the connections/grounds.

The following users liked this post:

samstoney (06-12-2019)

Trending Topics

#8

Thats pretty interesting. I’ve been looking around at connections and haven’t found anything. Power seems to be getting to the compressor, and the clutch is engaging.

I’ve always assumed the receiver drier was a bypass sort of affair, Butm if I understand correctly from the post you’re linking to this can plug the system. That would explain a lot - a restriction smaller than the evap valve restriction would allow the compressor to pump at pressure, but w/o enough flow through the evap valve to cool.

That looks to be my next step.

Sam

I’ve always assumed the receiver drier was a bypass sort of affair, Butm if I understand correctly from the post you’re linking to this can plug the system. That would explain a lot - a restriction smaller than the evap valve restriction would allow the compressor to pump at pressure, but w/o enough flow through the evap valve to cool.

That looks to be my next step.

Sam

#9

#10

Thats pretty interesting. Iíve been looking around at connections and havenít found anything. Power seems to be getting to the compressor, and the clutch is engaging.

Iíve always assumed the receiver drier was a bypass sort of affair, Butm if I understand correctly from the post youíre linking to this can plug the system. That would explain a lot - a restriction smaller than the evap valve restriction would allow the compressor to pump at pressure, but w/o enough flow through the evap valve to cool.

That looks to be my next step.

Sam

Iíve always assumed the receiver drier was a bypass sort of affair, Butm if I understand correctly from the post youíre linking to this can plug the system. That would explain a lot - a restriction smaller than the evap valve restriction would allow the compressor to pump at pressure, but w/o enough flow through the evap valve to cool.

That looks to be my next step.

Sam

#11

#12

Well, that didn’t work. New receiver, new evap valve, ac system runs but no cold. The shop that filled it says the compressor is kicking out before it makes cold,

I'm thinking next step *is* to read the sensor data, etc with a scanner. Before I go make the investment of a scanner, does anyone know where how to do this with a particular scanner this might be documented?

baring that, any other suggestions?

I'm thinking next step *is* to read the sensor data, etc with a scanner. Before I go make the investment of a scanner, does anyone know where how to do this with a particular scanner this might be documented?

baring that, any other suggestions?

#14

I got the the Schwaben scanner; nice piece of kit. Its nice being able to see when the compressor is running, sensors, etc. I reset an AC pressure sensor error and a “junction box 2” error, which I think was the AC relay, but nothing changed. Theres been a lot going on with filling, draining, testing, so theres a good chance that these were legacies of some sort of troubleshooting that I, or the garage working on this tried. The errors didn’t come back, and no other errors. What I do see is that the Mini system seems to turn the AC compressor on/off for different things, which may have been keeping me or the garage from seeing what was really going on inside the mechanical system itself.

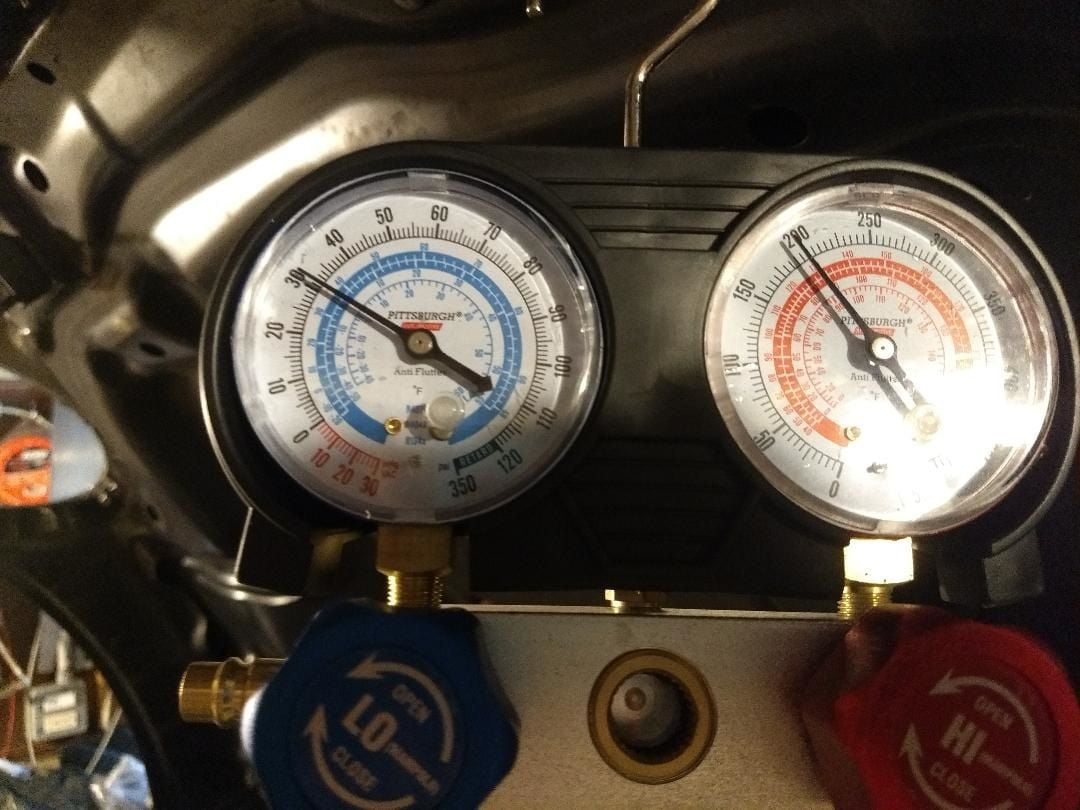

To make sure I was dealing with the AC system alone, and no Mini software, I ran 12V directly to the AC compressor clutch solenoid. Sure enough, the pressure increases on the high side, wavers a bit, then settles in with a low pressure of ~25PSI and a high of 200PSI at about 75 degreesF. From what I read, this low for the low, and high for the high. To me it implies that the compressor and clutch are working fine, and I’m guessing from the way the pressure wavered up and down before settling in, that the expansion valve is also doing its job. But - no cold air.

I have an IR temperature gun, and Ive been taking measurements wherever I can get to bare aluminum, and the temps everywhere are in within 10 or so degrees. At the receiver inlet a double are within a couple of degrees. At the firewall, where the expansion valve is, they are generally within about 5-10 degrees.

This leads me to believe I have some sort of obstruction in the system that is limiting the flow rate of the R134a so it cant do its job of transferring heat. I’m on my second new receiver/dryer, and second evaporator valve. They aren't Mini OEM bits, but when I look at the ones I replaced they look perfectly functional. So far, every fill/drain of R134a has been done with proper reclamation and vacuum equipment, so I think moisture can be safely ruled out.

Any suggestions as to where there might be other restrictions in the system? Is there any sort of spray orifice after the evaporator valve? I’m guessing that the next best step is to take *everything* apart and blow out with compressed air to try to find an obstruction. That seems like a miserable job, and a last resort. Anyone have a better suggestion?

To make sure I was dealing with the AC system alone, and no Mini software, I ran 12V directly to the AC compressor clutch solenoid. Sure enough, the pressure increases on the high side, wavers a bit, then settles in with a low pressure of ~25PSI and a high of 200PSI at about 75 degreesF. From what I read, this low for the low, and high for the high. To me it implies that the compressor and clutch are working fine, and I’m guessing from the way the pressure wavered up and down before settling in, that the expansion valve is also doing its job. But - no cold air.

I have an IR temperature gun, and Ive been taking measurements wherever I can get to bare aluminum, and the temps everywhere are in within 10 or so degrees. At the receiver inlet a double are within a couple of degrees. At the firewall, where the expansion valve is, they are generally within about 5-10 degrees.

This leads me to believe I have some sort of obstruction in the system that is limiting the flow rate of the R134a so it cant do its job of transferring heat. I’m on my second new receiver/dryer, and second evaporator valve. They aren't Mini OEM bits, but when I look at the ones I replaced they look perfectly functional. So far, every fill/drain of R134a has been done with proper reclamation and vacuum equipment, so I think moisture can be safely ruled out.

Any suggestions as to where there might be other restrictions in the system? Is there any sort of spray orifice after the evaporator valve? I’m guessing that the next best step is to take *everything* apart and blow out with compressed air to try to find an obstruction. That seems like a miserable job, and a last resort. Anyone have a better suggestion?

Last edited by samstoney; 06-22-2019 at 10:52 AM.

#15

Try this and report evaporator temp & temp control door position:

Conditions:

1. Scanner connected; under "main groups" select 'Control Units". Then select "body". Scroll down to #25 "IHKS; then select "live data". Select #3, Status, heater A/C Control. Check the box for "Evaporator temperature" and then press F3. With the scanner connected, AC on, and temp control set to full cold, go for a drive and report back with your lowest temperature reading.

2. Press "back" and go to the live data menu, select #6 "flap position, temperature; check the box on the next screen for "position, temperature mixing flap" Press F3. Cycle the temp control **** to full hot. What is your percent reading? Then cycle to full cold. What is your percent reading?

Conditions:

1. Scanner connected; under "main groups" select 'Control Units". Then select "body". Scroll down to #25 "IHKS; then select "live data". Select #3, Status, heater A/C Control. Check the box for "Evaporator temperature" and then press F3. With the scanner connected, AC on, and temp control set to full cold, go for a drive and report back with your lowest temperature reading.

2. Press "back" and go to the live data menu, select #6 "flap position, temperature; check the box on the next screen for "position, temperature mixing flap" Press F3. Cycle the temp control **** to full hot. What is your percent reading? Then cycle to full cold. What is your percent reading?

#16

Epilogue: I tore the system down and checked flow through each component, starting at the compressor and working back. When I got to the hard pipe going from the receiver to the expansion valve, I found it was plugged solid, right after the pressure switch. No amount of pressure, or special snakes would budge the plug, though an old speedo cable did manage to snake through all the bends and locate the obstruction.

In the end I had to cut the line open to get to the obstruction. It was a small silicon plug - the type I use to seal systems up when I’m working on them. Totally a mechanic (me) error. Ordinarily, this would have been at the top of my checklist, but the system ran cold for nearly 6 months with that plug in the system, so I ruled out any assembly error in my troubleshooting. I still haven’t got my head around that.

Thanks, all, for your suggestions and support.

sam

In the end I had to cut the line open to get to the obstruction. It was a small silicon plug - the type I use to seal systems up when I’m working on them. Totally a mechanic (me) error. Ordinarily, this would have been at the top of my checklist, but the system ran cold for nearly 6 months with that plug in the system, so I ruled out any assembly error in my troubleshooting. I still haven’t got my head around that.

Thanks, all, for your suggestions and support.

sam

Last edited by samstoney; 07-24-2019 at 07:43 PM. Reason: Spelling

#18

Epilogue: I tore the system down and checked flow through each component, starting at the compressor and working back. When I got to the hard pipe going from the receiver to the expansion valve, I found it was plugged solid, right after the pressure switch. No amount of pressure, or special snakes would budge the plug, though an old speedo cable did manage to snake through all the bends and locate the obstruction.

In the end I had to cut the line open to get to the obstruction. It was a small silicon plug - the type I use to seal systems up when I’m working on them. Totally a mechanic (me) error. Ordinarily, this would have been at the top of my checklist, but the system ran cold for nearly 6 months with that plug in the system, so I ruled out any assembly error in my troubleshooting. I still haven’t got my head around that.

Thanks, all, for your suggestions and support.

sam

In the end I had to cut the line open to get to the obstruction. It was a small silicon plug - the type I use to seal systems up when I’m working on them. Totally a mechanic (me) error. Ordinarily, this would have been at the top of my checklist, but the system ran cold for nearly 6 months with that plug in the system, so I ruled out any assembly error in my troubleshooting. I still haven’t got my head around that.

Thanks, all, for your suggestions and support.

sam

My 2008 Cooper s R56 with 155k miles has a new engine I installed on my own. AC wasnt blowing below 60F for some months before the engine swap so I dont think its at all related to the engine swap. My pressures with the original compressor were too low and the system wasnt accepting anymore r134a. I wasnt sure what was wrong exactly. I talked to a few BMW MINI specialists and they said...DEAD COMPRESSOR more than likely.

So I changed compressor, condenser, drier, expansion valve, pressure switch (all o-rings I had access to) and the evaporator temp sensor all with parts from ECS TUNING. Reputable stuff. I flushed the lines and evaporator with AC flush and shop air, so no oil was left in the system. Twuz dry and clean.

After all that, 58-60F at the vents. CRAP!

So I pulled the drier that came pre-installed in the Denso condenser and changed it with one from Behr/Hella (OEM style). Denso came with a bag-style drier. I lost maybe an ounce of PAG oil in the process and didnt add more PAG because I suspected I was overfilled with oil. The Denso drier bag looked kinda dirty. Suspicious considering I had flushed the system. But it might be PAG oil, since there was so much extra in the system.

I then vacuumed system for hours again, added 1 pound freon. No change. 60F at the vents.

My Autoenginuity scanner is having an issue getting correct temp readings at the moment (I have a trouble ticket out to them), so I put a laser thermometer on the evaporator where the temp sensor goes and I was getting 60-70F.

I checked the actuation of the HVAC heater mixing door (I have IHKA) and it moves. Not sure it works properly but it moves. I blocked the heater core lines with clamps and still getting 60F. So I think its the AC not the heater core mixing with AC air.

I then returned to my theory that I had too much PAG oil in the system. I investigated and found out SANDEN puts in 135 cc (4.5 ounces) of oil into the compressor. I had added 3.5 ounces on top of that so I was overfilled with oil. I removed about 2 ounces (+ 1 ounce I lost during drier swap = 3 ounces). Still 60F at vents.

I cannot get a temp of the hardline with a laser thermometer after the expansion valve because its behind the firewall. What should the temp of the hardlines be after the compressor but before the expansion valve?

Maybe one of the soft rubber lines is deteriorating and clogged or sent someting into the system and clogged something else? It was blowing 60F with the old compressor too after all.

Im lost.

Here's my AC pressures on 90F day (humidity not noted)

And here is video of the gauges at 90F. The low side fluctuates at idle which is strange. This was with the system overfilled with PAG oil.

Last edited by Lex2008; 07-29-2019 at 10:53 AM.

#19

Sounds exactly like what I was experiencing, right down to the weird fluctuating inlet pressure. I hate to say it, but I’d suggest taking the whole system apart and blowing air through all the static lines again to see if there is any blockage. If I had to do it again I’d start with the high pressure side, as that has the smaller, more likely to clog lines.

One thing that was very helpful to me was wiring the compressor clutch straight to 12V, so I was absolutely sure some bit of Mini software wasn't turning things off on me. With that hard wired on you know for sure you’re not fighting the electronics and you can focus on the plumbing 100%.

One thing that was very helpful to me was wiring the compressor clutch straight to 12V, so I was absolutely sure some bit of Mini software wasn't turning things off on me. With that hard wired on you know for sure you’re not fighting the electronics and you can focus on the plumbing 100%.

#20

Thread

Thread Starter

Forum

Replies

Last Post

rfhamner

Stock Problems/Issues

5

09-25-2017 09:10 AM