Mini Cooper 2014-Present: Suspension Modifications

The Mini Cooper is an extremely agile car. Make it even more responsive in the corner with these helpful suspension mods.

This article applies to the Mini Cooper/Cooper S (2014-Present).

Your vehicle's suspension plays a huge role in how the car handles and how smooth the ride is when transitioning from street to track, or just transitioning through slaloms at the autocross. There are many components which make up your vehicle's suspension system. This includes but is not limited to: struts or shocks, springs, tie rods, axles, ball joint, control arms, sway bars, etc. Each of these components are now available through the aftermarket companies with upgraded design and durability and have been built with the racing in enthusiast in mind. Many of the applications are intended for track use only, so be wise to what components you purchase and how you use them.

Suspension Modifications

Springs

DIY Cost – $200-400

Professional Cost – $500-800

Skill Level – Moderately Difficult; requires removal of existing spring and shock combo, as well as decompressing and "recompressing" springs on to existing or new shocks.

Aftermarket springs offer a lowered ride height and stiffer spring rates. This means that the car's center of gravity is lowered and the car's cornering, acceleration and braking flattened due to the stiffer springs. You can also fine tune the car's balance, most commonly by really increasing the rear spring rate to reduce corner-entry understeer.

Coilovers

DIY Cost – $1,000-3,000+

Professional Cost – $1,500-4,000+

Skill Level – Moderate; requires removal of shocks and struts but no decompression necessary. Simply swap in the units after setting your ride heights and dampening (if applicable).

Coilovers essentially replace both the springs and shocks at once and add a variable of adjustment. The user can lower the vehicle or raise it through use of coilover wrenches that allow the body spin up or down to setting the desired ride height. Some of the higher quality coilovers even have built in dampening for the strut portion of the coilover that is often handled through a simple dial. This adjustment can change the compression (bump) and rebound of the shock absorbers, which is excellent for making the car fast at different tracks, where each requires a different setup. Additionally, the front coilovers can be spec'd with an adjustable camber plate to greatly increase the available negative camber in the front end, aiding tire wear and improving cornering.

Sway Bars

DIY Cost – $200-400

Professional Cost – $300-600

Skill Level – Easy; requires installation of rigid bar with related bushings. Usually a direct replacement for factory sway bars and bushings.

Your Mini Cooper utilizes anti roll bars in the front and rear suspension; these bars effectively link the left and right sides together, reducing roll. Larger, stiffer bars can lessen roll and be used for fine tuning the car's handling balance after changing the springs and shocks. Generally speaking, a larger rear bar will reduce understeer on corner-entry, at the expense of peak cornering grip. A larger front bar may increase understeer at the limit, but improve turn-in sharpness.

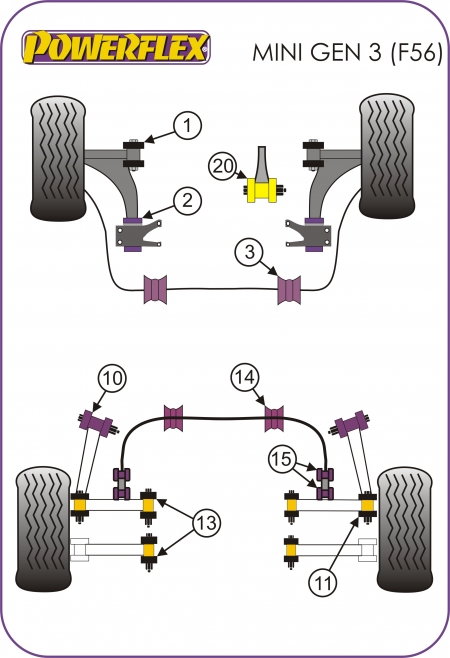

Suspension Bushings

DIY Cost – $25-300 (depending on which bushings are being replaced)

Professional Cost – $100-400

Skill Level – Moderately Easy; requires removal of old bushings and often the components which they are affixed to.

Original equipment bushings are made of rubber, and are generally designed to be soft and compliant, to reduce vibrations and harshness. That's great if you're commuting down the interstate, but it's bad when that commute goes through the twisty roads. These bushings are exceptionally prone to wear and tear and require regular replacement.

Aftermarket bushings are designed from a much stiffer polyurethane composite. This is good because poly generally doesn't degrade in the way that rubber does, and these will likely last the lifetime of the vehicle.

The other perk is that stiffer chassis bushings allow the suspension and tires to work much more efficiently. Soft bushings allow for excessive "deflection" or movement outside of the intended up/down compression/rebound that you suspension does. This means delayed response until the bushings stop moving, and finally allow the rest of the suspension to work properly. Soft or worn bushings also result in what is called "dynamic alignment change," which is bad. Does your Mini have unusual tire wear, but the alignment checks out? Your bushings are bad, and by allowing excessive movement under load, are pressing down on the tires unevenly, wearing them out and compromising grip.

Ideally, your subframe would be solidly mounted to the chassis, and the control arms (the suspension pieces that link the wheels to the subframe) would be fitted with the stiffest bushings possible to limit deflection and allow the suspension to work correctly. In short, go poly, and don't look back. Thank us later.

Chassis Bracing

DIY Cost – $200-400

Professional Cost – $250-600

Skill Level – Moderately Easy; will require access to a lift or at least get the vehicle high enough on level ground. These plates either replace or install in place of existing braces.

Chassis braces are fitted from the factory on most sporting models. However, if you have a base Mini, you may not have as many, or the same ones as an "S" or "JCW" model. Of course you can always buy those OEM parts, or you can go aftermarket.

The premise of chassis bracing is to "tie" together areas prone to flexing over broken pavement or under hard cornering. We highly recommend doing these as a last measure, as their efficacy is minor compared to springs, shocks or sway bars.

Related Discussions

- NM and Cravenspeed Lower Springs - NorthAmericanMotoring.com

- Coilovers - NorthAmericanMotoring.com

- NM Swaybar - NorthAmericanMotoring.com

- Powerflex Bushings - NorthAmericanMotoring.com

- Cravenspeed Big Pair Braces - NorthAmericanMotoring.com