Hairline Cracking In Rotors?

#1

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

Hairline Cracking In Rotors?

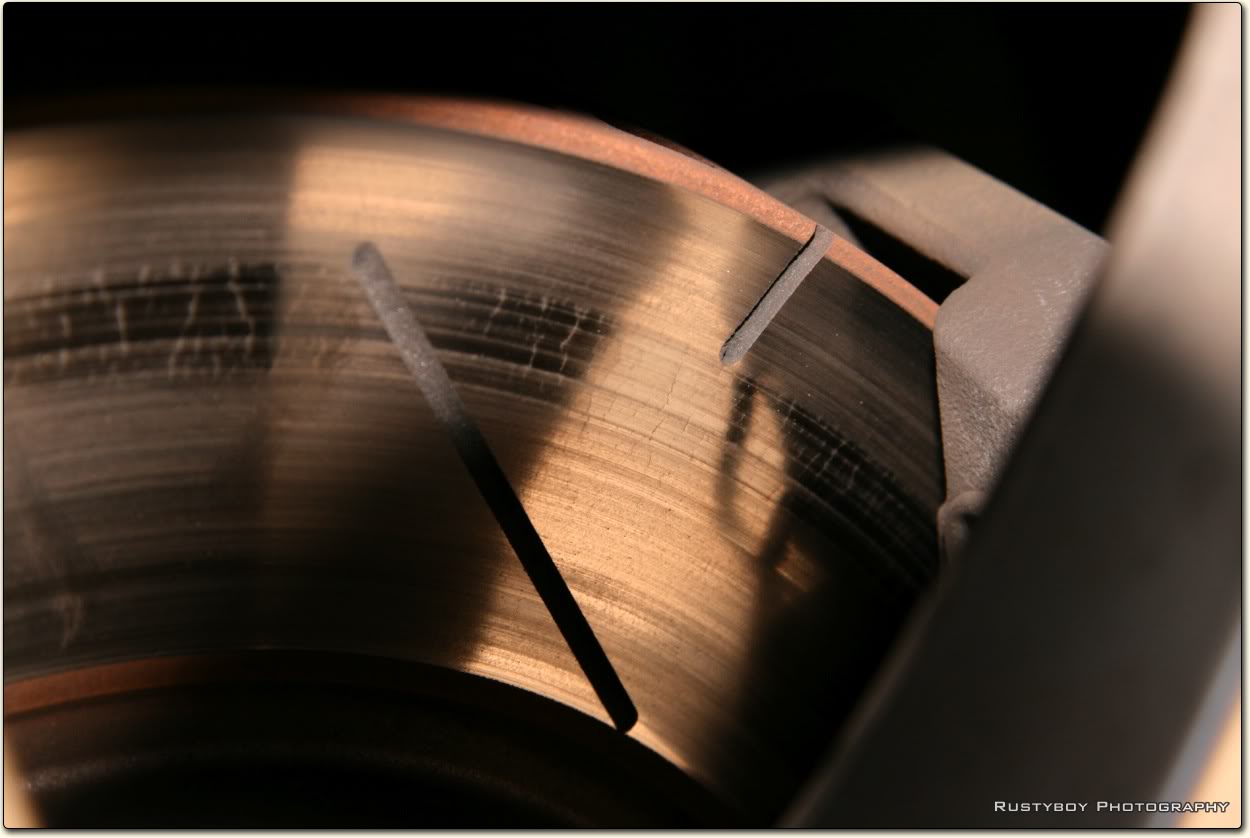

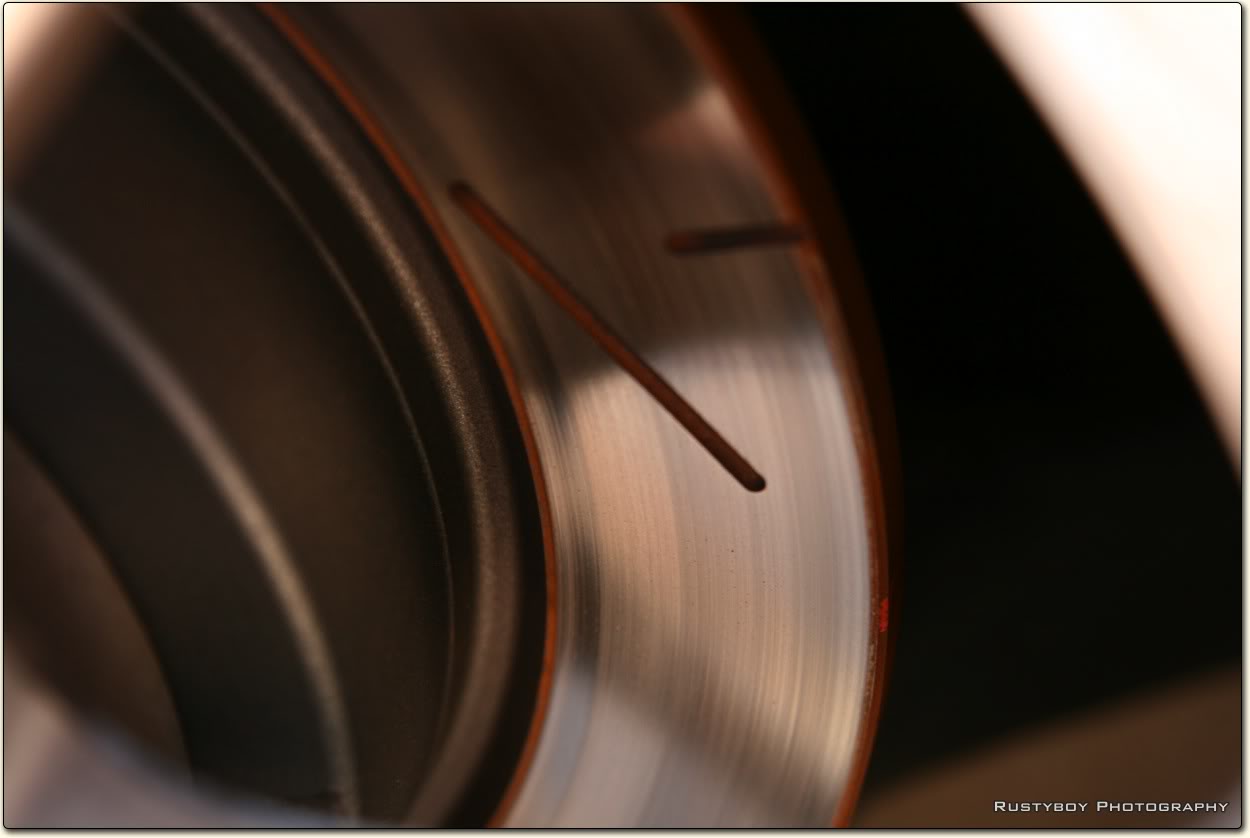

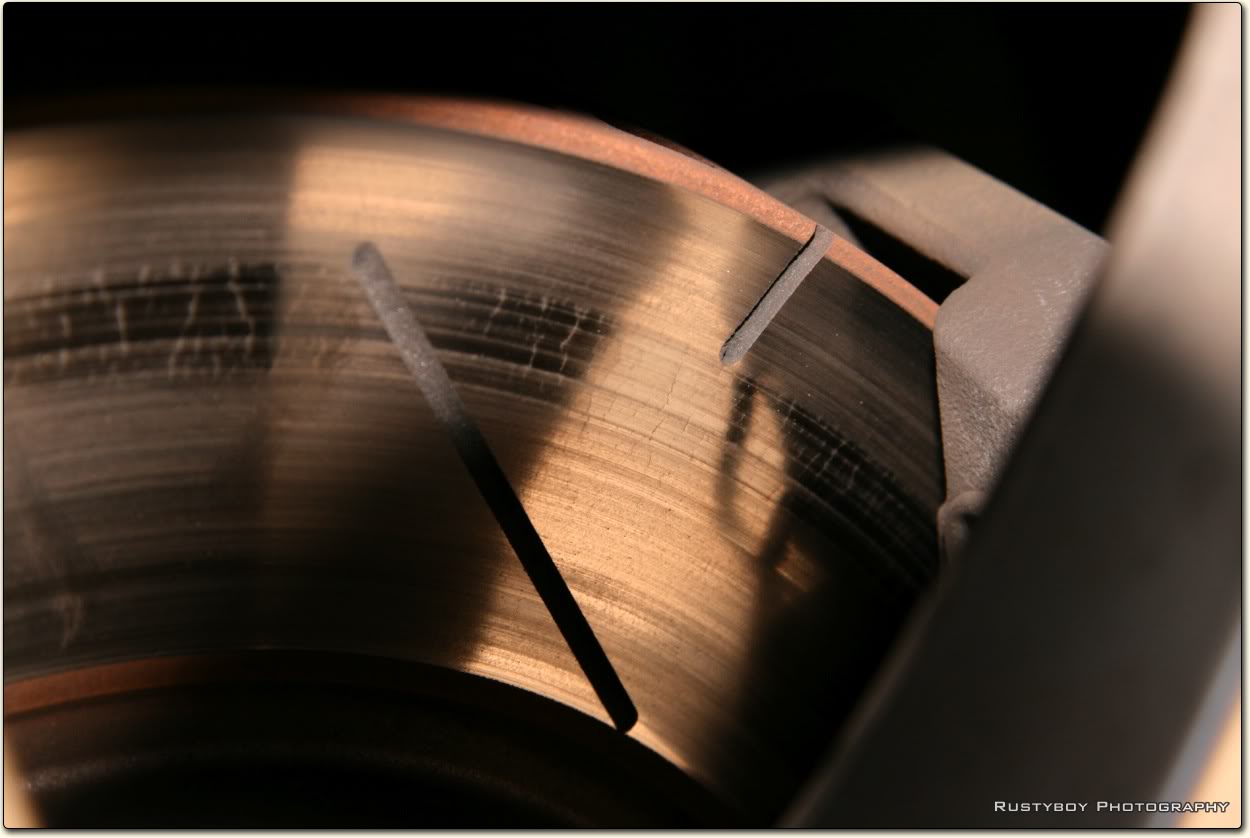

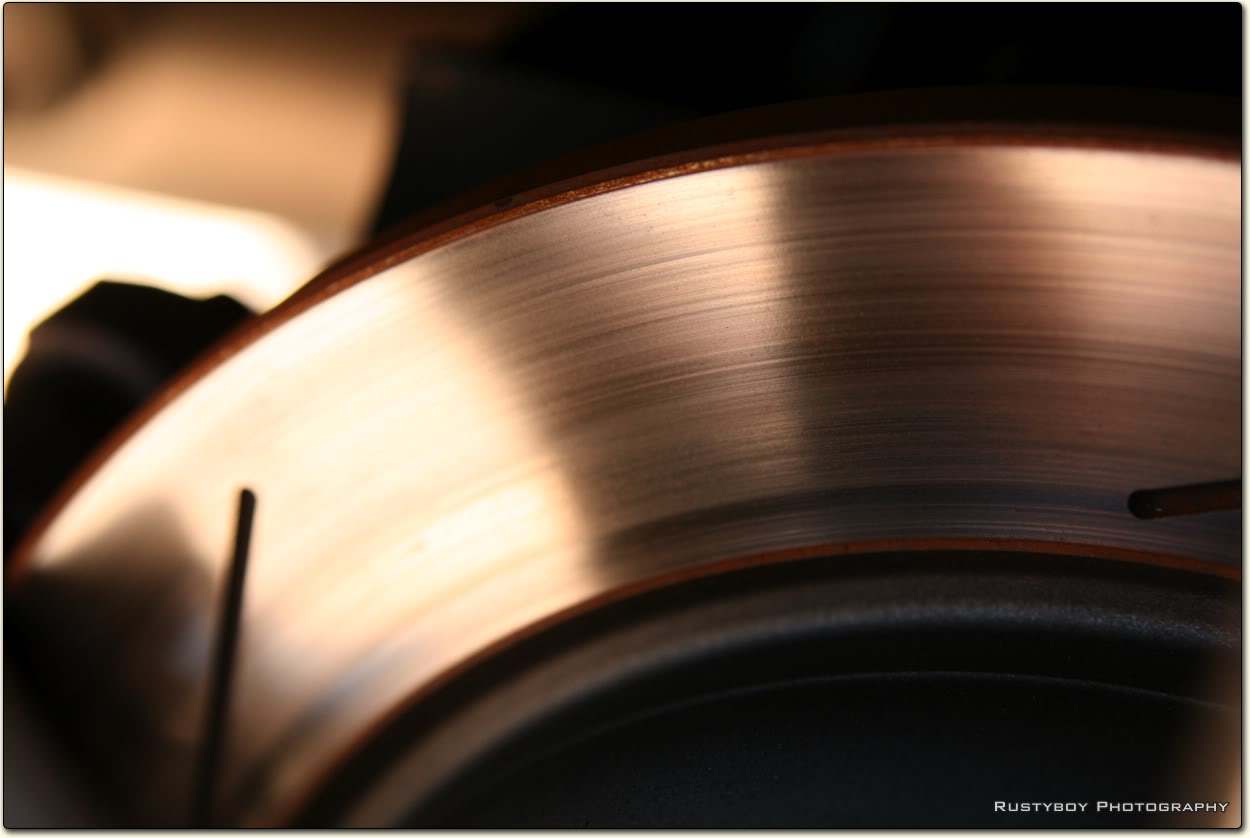

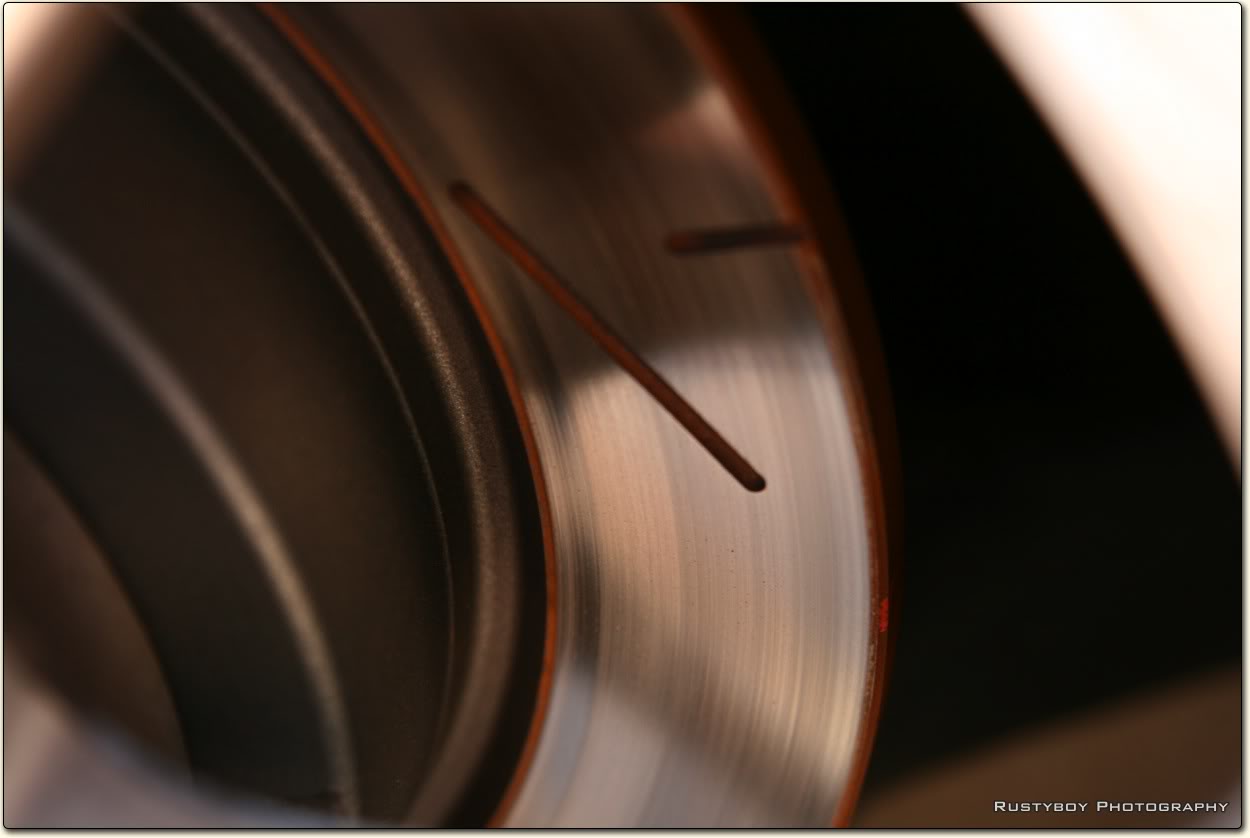

Anyone think this is any cause for concern? I'm swapping them out soon anyway, but I thought i'd get some opinions. The cracks appear to be on the surface, but running my finger along them, it appears to be smooth. The car is tracked hard, but i've never seen hairline fractures like this in solid vented rotors, typically only in x-drilled rotors.

Front Rotors:

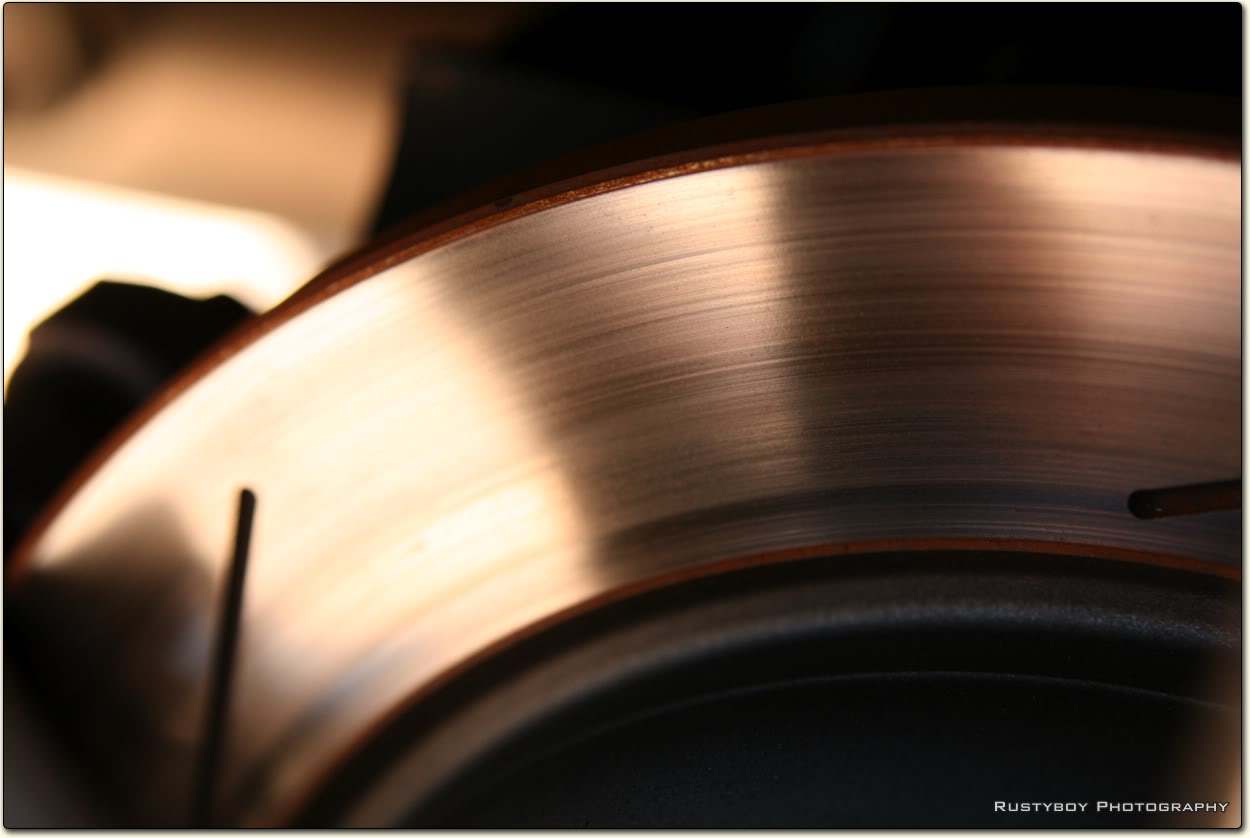

By comparision my rear rotors are completely smooth, with no visible cracking

Front Rotors:

By comparision my rear rotors are completely smooth, with no visible cracking

Last edited by Guest; 03-24-2008 at 06:34 PM. Reason: Photos Resized to Reduce Thread Load Time

#2

#3

#4

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

They're Mintex xTreme pads specifically made for the MCS. Only thing I can think of is that a rock or something got stuck in between the pad and rotor and somehow caused more heat buildup. I'll have to take a look at the other side, that's the passenger side rotor.

#5

#7

Trending Topics

#8

This is actually a good rule of thumb to follow. My rotors look similar to the ones first pictured by the OP and I'm not stressing. With the amount of heat that builds, espespecially with HP aftermarket pads, there's more than likely going to be some very (and I mean very) minor cracking. You more than likely won't see this with a less hard OE pad.

#9

#10

Normal wear and tear for an oem rotor enduring high temp use. The added Cf of a good pad elevated the work of the front rotor to the point it is now operating at the limits of its capacity and stress cracking would be considered normal.

Not a lot you can do about it. Buy replacements of low cost knowing you'll replace them often or consider a BBK for the added mass. Air ducting to help cool the oem part may by you some time too.

The rears are along for the ride regardless.

Not a lot you can do about it. Buy replacements of low cost knowing you'll replace them often or consider a BBK for the added mass. Air ducting to help cool the oem part may by you some time too.

The rears are along for the ride regardless.

#11

But you also watch and be sure that the pads reach proper operating temperature and stay there. Pad efficiency will be reduced if they are run too cool. A drop in temperature is good to an extent but is brake duct cooling really required on a street only car?

#13

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

Normal wear and tear for an oem rotor enduring high temp use. The added Cf of a good pad elevated the work of the front rotor to the point it is now operating at the limits of its capacity and stress cracking would be considered normal.

Not a lot you can do about it. Buy replacements of low cost knowing you'll replace them often or consider a BBK for the added mass. Air ducting to help cool the oem part may by you some time too.

The rears are along for the ride regardless.

Not a lot you can do about it. Buy replacements of low cost knowing you'll replace them often or consider a BBK for the added mass. Air ducting to help cool the oem part may by you some time too.

The rears are along for the ride regardless.

#14

cracking up?

toddtce is correct- that is perfectly normal and nothing to be worried about. I'm more concerned about the fact that you paid money for vented rotors that aren't venting anything. Did anyone notice that the vent does not extend to the end of the rotor? Where is the gas supposed to go? I would call up your manufacturer and ask what the deal is?

Unless your doing some serious racing, a BBK is a waste of money (check out mc2 March edition). And if you are going to race, most of the race series out there (SCCA & NASA) require stock OEM rotors anyway. The only series that would allow for a BBK would be the Koni Mini Challenge. I believe that it only runs in teh UK and Australia. Testing has shown that OEM rotors perform at the same levels as non-OEM's in stopping distance. All you need is a good brake pad. (check out www.autoxcooper.com-those guys have it together.)

Unless your doing some serious racing, a BBK is a waste of money (check out mc2 March edition). And if you are going to race, most of the race series out there (SCCA & NASA) require stock OEM rotors anyway. The only series that would allow for a BBK would be the Koni Mini Challenge. I believe that it only runs in teh UK and Australia. Testing has shown that OEM rotors perform at the same levels as non-OEM's in stopping distance. All you need is a good brake pad. (check out www.autoxcooper.com-those guys have it together.)

#15

While I appreciat Mike's vote of confidence on the rotor above, I'll have to respectfully disagree with his postion on the value of the BBK. The reasson we see the thermal cracks above is that it's operating beyond its capable duty cycle. While there remains little stopping distance improvement in the BBK as pointed out, the value of the BBK is not about stopping the shortest, it's about stopping the same over and over. By increasing rotor diameter the effectiveness and efficiency is improved. Thus the duty cycle is lower. Where this rotor is operating at or near peak duty cycle the larger rotor can achieve the same stopping effectiveness over and over and for a longer time as it only requires 85% duty cycle to ahcieve the same result. As rotor size (both OD and width) increase this value continues to improve. Clearly there are some benefits to a 13 x 1.25" 15lb rotor for the most sever duty use! Finding the balance of how much is enough vs how much is too much varies by the designer, the user and the intended application. A giant masive rotor for street use and Autocross is of little value. A larger and meatier rotor for track day use and greater heat saturation is a winner. One might trade some other value such as rotational mass and acceleration for; not better braking...but sustained braking. Mike's comments on the venting mirrors my own any longer. I'm slowly moving (back) to a fully vented- to the edge gas vent pattern as new rotors replace old. Like other suppliers I opted to do the same "start/stop" pattern that is the norm. The problem is that they don't really vent anything. And they seem more prone to pulsation than those of old. I've been doing this since 1993 and have yet to have a rotor crack at the gas vent solely due to the vent running to the edge. Drilled; yes, lile all the others.... As for continued use of the rotors in question, I'd keep an eye on them and if the cracks become larger (which they will) I would pull them. Addiing some better pads will help with the bite on the rotor also however if you try to elevate this too much you'll be back in the duty cycle problems all over again do to over taxing this casting even further.

#17

i just went out and checked my rotors! they look nothing like the OP's. i have todd's 13" X .81 front rotors. i will soon be purchasing my third set of front rotors and the second set for the rear. no cracking, just getting skinny. i know that todd routinely says that BBK's don't decrease stopping distance and just resist fade better. i will tell you that on my car, the stopping distance is sick short! while still driving w/ instructors at DE's, my last instructor described my car as a set of brakes w/ a car attatched. he could not believe how deep i could (and would) go. i've gone with progressively higher torque pads as i have gone with stickier tires. stopping (slowing) distances have become a function of *****, not brakes. OP, i highly recommend a BBK from TCE (and dedicated track pads).

#19

I'll toss out some thoughts on the dark band; pad smear from the pads chunking in the middle (need pad pic), stress cracks providing air flow to that portion of the rotor changing pad to rotor contact, or iron particulates tearing from the rotor surface and cracks smearing on the friction surface.

"What is pad smear for 200 please."

#21

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

i just went out and checked my rotors! they look nothing like the OP's. i have todd's 13" X .81 front rotors. i will soon be purchasing my third set of front rotors and the second set for the rear. no cracking, just getting skinny. i know that todd routinely says that BBK's don't decrease stopping distance and just resist fade better. i will tell you that on my car, the stopping distance is sick short! while still driving w/ instructors at DE's, my last instructor described my car as a set of brakes w/ a car attatched. he could not believe how deep i could (and would) go. i've gone with progressively higher torque pads as i have gone with stickier tires. stopping (slowing) distances have become a function of *****, not brakes. OP, i highly recommend a BBK from TCE (and dedicated track pads).

I'm not sure why the gas slots don't go all the way to the rotors edge, the general consensus with slotting appears to be that they're much better at wiping the pads clean than actually helping with pad outgassing.

http://www.tirerack.com/brakes/brake...0+Series+Rotor

Those are the rotors I have. They've definitely been up there in the temperature range, Last track day I hit them with an IR thermometer and they were over 1100 degrees.

I've already spoken to Autoxcooper and we're working something out for new pads once I get the front brakes sorted out

.

.

#22

BTW;

So why the small band of dark material (pad material) only in one area???

Pull the pads out and put a straight edge on the back side. I have $20 says the backing plate looks like a banana. All the work is being done at the center of the pad due to the pad deflection under the required high pressure being exerted upon it. As it gets hot it begins to deform which only goes to make the center portion run hotter and hotter...a slippery slope that does not get better.

So why the small band of dark material (pad material) only in one area???

Pull the pads out and put a straight edge on the back side. I have $20 says the backing plate looks like a banana. All the work is being done at the center of the pad due to the pad deflection under the required high pressure being exerted upon it. As it gets hot it begins to deform which only goes to make the center portion run hotter and hotter...a slippery slope that does not get better.

#23

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

BTW;

So why the small band of dark material (pad material) only in one area???

Pull the pads out and put a straight edge on the back side. I have $20 says the backing plate looks like a banana. All the work is being done at the center of the pad due to the pad deflection under the required high pressure being exerted upon it. As it gets hot it begins to deform which only goes to make the center portion run hotter and hotter...a slippery slope that does not get better.

So why the small band of dark material (pad material) only in one area???

Pull the pads out and put a straight edge on the back side. I have $20 says the backing plate looks like a banana. All the work is being done at the center of the pad due to the pad deflection under the required high pressure being exerted upon it. As it gets hot it begins to deform which only goes to make the center portion run hotter and hotter...a slippery slope that does not get better.

.

. Do you know off the top of your head whether Carbotech makes pads that will fit the Wilwood kits you sell?

I'm definitely going to shoot some photos of the pads when they come out.

#24

All the work is being done at the center of the pad due to the pad deflection under the required high pressure being exerted upon it. As it gets hot it begins to deform which only goes to make the center portion run hotter and hotter...a slippery slope that does not get better.

#25

Join Date: Aug 2005

Location: SoCaL (Agoura Hills)

Posts: 3,902

Likes: 0

Received 2 Likes

on

2 Posts

At high temperatures the pad deforms and bows out in an arc (See Banana Comment). This concentrates all the heat and pressure on a single point on the rotor rather than across the entire pad swept surface.

Todd can likely explain it better than I can, but it's not something that a stiffening kit will solve. Unfortunately if you're going to be tracking your car on a track with intensive braking points, you need a BBK, or at the very least you need to expect to change your rotors out every 8-10k miles.