DIY For Timing Chain Replaement

#26

Thanks for the pointers, guys. I bought the cam locking tools and now fully understand the need for them. My compression problem was a bit of a pita to diagnose. I welded half an old spark plug to a spare compression gauge fitting I had, to read compression. That wasn't perfect (leaked a little) but worked well enough to determine Cyl #1 has no compression where others did. Then I bought a leakdown test kit from harbour freight, which surprisingly, came with the 14mm MINI plug threading adapter. Leakdown told me exhaust valve ( I placed latex gloves over the tailpipes) which disappointed me as I'd hoped it was intake due to carbon on valves. I also finally understand assembly mode now, and I'm 80% there to removing the head. Just hope I can get all this shizl back together again.

If I get it running and have codes I can't get to stop throwing, my backup plan is to bring it in for the electric waterpump recall and maybe MINI tech's will spot any plumbing connectors I botched. Fun to keep getting calls/letters from MINI dealers asking me to bring the car in for that recall or as a trade on a new MINI, but asking them if they'll pay for the tow truck from my garage usually quiets them down.

If I get it running and have codes I can't get to stop throwing, my backup plan is to bring it in for the electric waterpump recall and maybe MINI tech's will spot any plumbing connectors I botched. Fun to keep getting calls/letters from MINI dealers asking me to bring the car in for that recall or as a trade on a new MINI, but asking them if they'll pay for the tow truck from my garage usually quiets them down.

#27

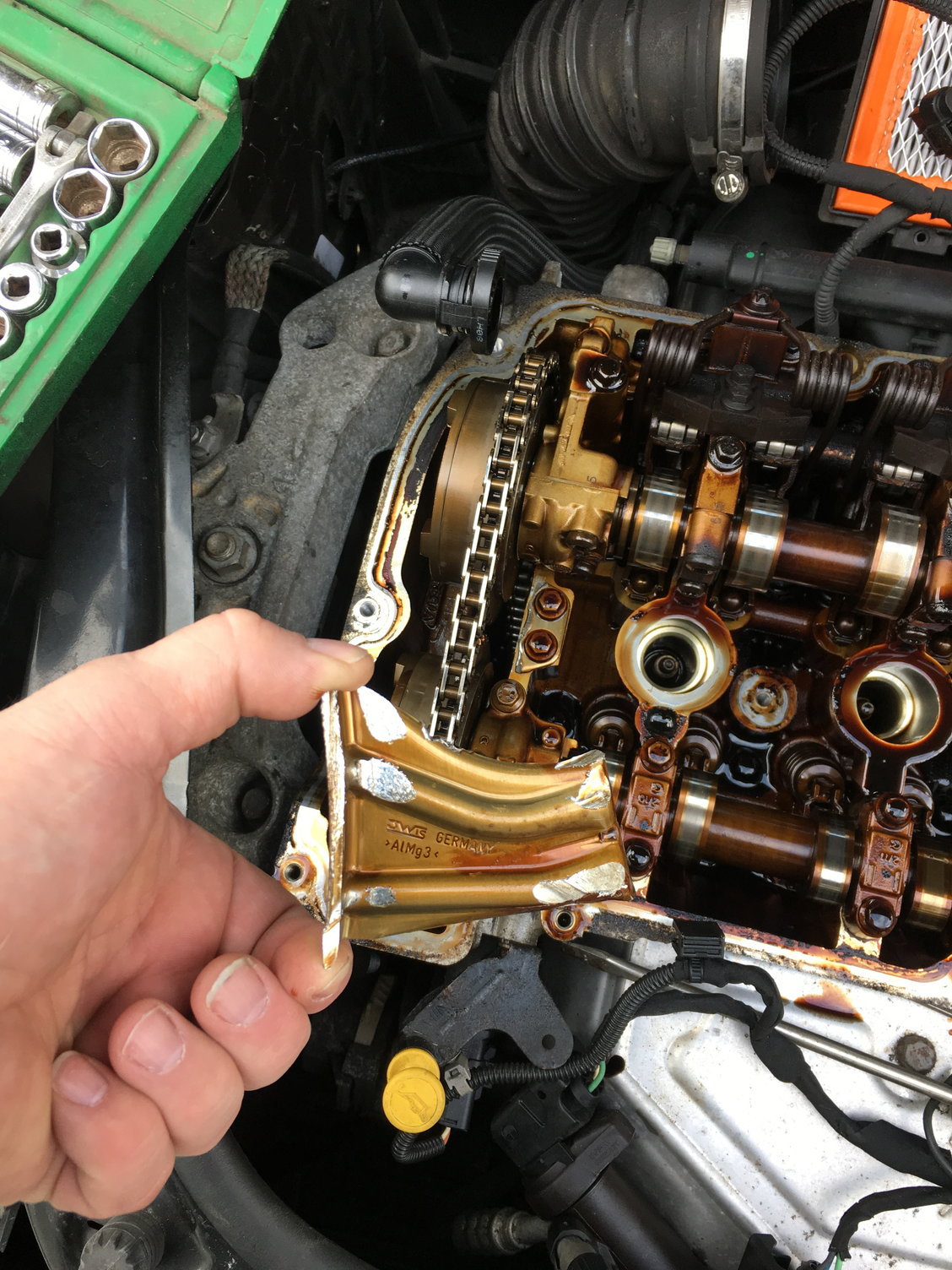

Head's off, chain removal more steps then I thought

I'm definitely not a fan of the BWM TIS electronic manual. I thought with the head completely off, there'd be a master link or some straight forward way to replace my timing chain. Finally found the procedure for chain replacement, and naturally, I need to remove crank pin so that crank sprocket is free before I can remove the timing chain. Should have assumed that. Anyway, wanted to know if my crank locating tool (flywheel) is enough to hold the crank when I release the crank bolt? TIS shows a tool that is screwed to the crank hub 11 9 280 and you push that against the rotation of the crank pin (bolt). Should I plan to have to make or purchase that tool or can I back the crank pin bolt out with the flywheel lock holding crank in place (and retorque later). TIS doesn't tell me to replace front seal or crank pin, so I'm not clear if that bolt's a stretcher like the two cam sprocket ones are. Can I do this crank pin with the motor in? Should I be working through the wheel arch? I thought I was close to reassembling, but now I'm reading about disconnect the A/C line from the compressor before all of this. What a nightmare this job has become.

I'll include some nightmarish head shots, for your entertainment (90k miles, car quit running with burnt exhaust valve)

https://www.northamericanmotoring.co...64-post11.html

I'll include some nightmarish head shots, for your entertainment (90k miles, car quit running with burnt exhaust valve)

https://www.northamericanmotoring.co...64-post11.html

Last edited by karlInSanDiego; 06-11-2012 at 08:35 PM.

#28

Karl, I would probably make something to hold the crank. I think the torque when I removed mine was around 120-130 ft-lbs and that pin doesn't go in that far. It might hold but I didn't want to risk damaging the tool, flyweel or case. The crankbolt needs to be replaced. Also, the torque on it changed from when the Bentley manual was printed (mine anyway) the initial torque is right but the final angle should be 180 deg instead of 100 deg (please check this yourself, I will not be responsible for your bolt breaking if it is torqued wrong!). I didn't replace my front seal, it looked OK and I think it could be replaced with out removing the crankbolt. The timing chaing can be replaced with the motor in and yes, work mainly through the wheel arch. The procedure I followed requires the removal of the engine mount on that side and then I supported the engine with a jack stand under one of the A/C mounts. You shouldn't need to unhook the A/C lines. Did you put the front bumber/radiator support in the service position? Things are tight but eventually, if you cut off a finger or two and scrape off most of one arm you can probably get to everything

#29

So, has anyone actually successfully done this in their own garage? Or even attempted it without success  ? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

Do you by any chance still have the tools you used for this

#30

Would you guys like me to write a detail & in depth DIY How To timing chain replacement (for n14) with pictures? I am tempted to do so just to make sure that those DIY'ers out there who are willing to attempt doing it, do it right the first time as I would hate to see a kaput N14 due to a minor miss when attempting this job. On a scale of 1-10 with 10 being a engine overhaul and a 1 being rotation of tires, i'd place this job at around a 6, maybe 5 for someone who is experienced and has the proper tools to do the job. While its straight forward there are some key things I have learned over the 100's of Timing Chains I've done (sequences and best practices) that will ensure your attempt is right and spot on with no hiccups.

Let me know.

Let me know.

#33

#34

Would you guys like me to write a detail & in depth DIY How To timing chain replacement (for n14) with pictures? I am tempted to do so just to make sure that those DIY'ers out there who are willing to attempt doing it, do it right the first time as I would hate to see a kaput N14 due to a minor miss when attempting this job. On a scale of 1-10 with 10 being a engine overhaul and a 1 being rotation of tires, i'd place this job at around a 6, maybe 5 for someone who is experienced and has the proper tools to do the job. While its straight forward there are some key things I have learned over the 100's of Timing Chains I've done (sequences and best practices) that will ensure your attempt is right and spot on with no hiccups.

Let me know.

Let me know.

#36

#37

This is an old thread, but since I just pulled the head to inspect lack of compression on cyl 4, the timing chain job came along for the ride.

I bought the MINI special tool off eBay for $65 shipped (link below), and it worked like a charm. I also relied on Bentley for high-level instructions and bolt tightening torques, which are essential for completing this job.

Super high-level (email me if you need more details):

Step 0: If you are pulling the head, unbolt intake and exhaust manifolds. Otherwise, ignore.

Step 1: Remove valve cover, then rotate the engine (socket on crankshaft bolt - remove passenger front wheel well liner to get to it!) until the lettering on intake/exhaust camshafts is facing up. This also is 1 of the two positions where you can lock the cams with the special tool, but the only position where the flywheel lock fits into place.

Step 2: Insert the flywheel lock (locks crankshaft), and lock down the cams by placing MINI special tool intake/exhaust cam locking contraptions in place.

Step 3: Remove chain tensioner (some oil will leak out), remove the upper chain guide rail (2 bolts).

Step 4: Remove chain guide-rail bolts (passenger side of the engine block, above crankshaft pulley). To get to them, a whole bunch of things need to come out (belt, tensioner, etc).

Step 5: With cams locked solid (2x check!), remove the intake/vanos pulley, and find a solution for holding the chain up (vs. dropping it into the oil pan). A bungee cord attached to the hood latch worked for me.

Step 6: Remove the exhaust pulley (bolts are NOT re-usable, so make sure you buy new replacements!)

Step 7: Remove camshaft sprocket/damper hub fastener (this is a good time to remove/replace crankshaft seal)

Step 8: Pull out the old chain with cassette and lower sprocket as one package.

Step 9: Drop the oil pan and fish out all the pieces of the old guide-rail. You will now be doing an oil change.

Step 10: Use Bentley manual to sequence the re-installation of all the parts, and torque all the bolts back to spec. There are some special steps that need to be followed, so do buy the manual to complete the job properly.

That's about it.

I may be forgetting something, in which case, drop me a line and I will edit this post.

The above is a gross over-simplification of the steps, which have a book value of ~8 hours of labor at the dealership. Figure about 3x if you are DIY-ing in your garage for the first time (as in allocate at least 3 days to complete the job, assuming all parts are present).

a

P.S.: Parts you will need: new timing chain kit, new tensioner, new sprocket bolts (intake/exhaust cam shafts, crankshaft), oil change supplies (oil, filter, etc).

P.P.S.: eBay MINI camshaft lock tool:

http://www.ebay.com/itm/201187631486?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

a

I bought the MINI special tool off eBay for $65 shipped (link below), and it worked like a charm. I also relied on Bentley for high-level instructions and bolt tightening torques, which are essential for completing this job.

Super high-level (email me if you need more details):

Step 0: If you are pulling the head, unbolt intake and exhaust manifolds. Otherwise, ignore.

Step 1: Remove valve cover, then rotate the engine (socket on crankshaft bolt - remove passenger front wheel well liner to get to it!) until the lettering on intake/exhaust camshafts is facing up. This also is 1 of the two positions where you can lock the cams with the special tool, but the only position where the flywheel lock fits into place.

Step 2: Insert the flywheel lock (locks crankshaft), and lock down the cams by placing MINI special tool intake/exhaust cam locking contraptions in place.

Step 3: Remove chain tensioner (some oil will leak out), remove the upper chain guide rail (2 bolts).

Step 4: Remove chain guide-rail bolts (passenger side of the engine block, above crankshaft pulley). To get to them, a whole bunch of things need to come out (belt, tensioner, etc).

Step 5: With cams locked solid (2x check!), remove the intake/vanos pulley, and find a solution for holding the chain up (vs. dropping it into the oil pan). A bungee cord attached to the hood latch worked for me.

Step 6: Remove the exhaust pulley (bolts are NOT re-usable, so make sure you buy new replacements!)

Step 7: Remove camshaft sprocket/damper hub fastener (this is a good time to remove/replace crankshaft seal)

Step 8: Pull out the old chain with cassette and lower sprocket as one package.

Step 9: Drop the oil pan and fish out all the pieces of the old guide-rail. You will now be doing an oil change.

Step 10: Use Bentley manual to sequence the re-installation of all the parts, and torque all the bolts back to spec. There are some special steps that need to be followed, so do buy the manual to complete the job properly.

That's about it.

I may be forgetting something, in which case, drop me a line and I will edit this post.

The above is a gross over-simplification of the steps, which have a book value of ~8 hours of labor at the dealership. Figure about 3x if you are DIY-ing in your garage for the first time (as in allocate at least 3 days to complete the job, assuming all parts are present).

a

P.S.: Parts you will need: new timing chain kit, new tensioner, new sprocket bolts (intake/exhaust cam shafts, crankshaft), oil change supplies (oil, filter, etc).

P.P.S.: eBay MINI camshaft lock tool:

http://www.ebay.com/itm/201187631486?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

a

#38

The following users liked this post:

Clark Kent (11-27-2020)

#39

Great write up! I think we are going to do a DIY on this as well.

-Luccia

-Luccia

__________________

Your Trusted Source For DIY and Parts

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

#41

It's definitely on the list! Be sure to keep an eye out. We have a thread posted here and I'll be updating it once new content is up and out for the R56. If you want to add more be sure to post in that thread so I can add it to the list.

-Luccia

-Luccia

__________________

Your Trusted Source For DIY and Parts

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

#42

Timing chain replacement on a 2007-2010 Mini Cooper with the Death Rattle

I've done a lot of reading and a lot of video-watching on this subject (I'm literally up over 10 hours of video-watching and note-taking plus hours of reading and saving files), and I have a few observations:

1. This can be a DIY job for a LOT less money than taking it to the dealer, but watch the best video first. It's three hours long. Stop and take notes on tools and parts. After this video, the job itself is probably six to 10 if you work fast.

2. The parts come in a kit: chain, tensioner, new guides. You should also buy the bottom sprocket and MAYBE the upper ones, if there is significant damage. And see below on other vital parts which are in some kits but not others.

3. The man who did the long video:

(part 1, a good hour long) really knows his stuff. Mentions every size socket needed, which makes a three-hour video a time-saver compared to having to shop for a 27 mm socket or the right spark plug socket or a 25 mm star socket when your car's halfway apart.

4. He also found that the chain had jumped, throwing the car out of timing. You will read practically EVERYWHERE that once the timing goes, there is no simply DIY way to get it back. Wrong. Watch his amazingly simple method on the video.

5. He paid $120 for the camshaft locking special tool, used. I got a new one for $56 on ebay.

6. If you don't have or don't want to buy the special BMW/Mini thin-walled 14mm long 12-point spark plug socket, use a six-point 15 mm and then a claw grabber to reach down and fish out and re-install, the spark plugs. The torque is low, so you're not going to hurt the plugs with the wrong width socket. You need the grabber anyway if you've ever dropped a nut or bolt.

7. Another expensive tool is the Mini tool to press the crankshaft seal (which you MUST replace) back in. He used a more generic crankshaft seal presser. I found a posting which says you can use the female coupling for a 2" PVC pipe (not the pipe itself, which is too small in diameter) plus a block of wood and a hammer to tap it in. The coupling cost me $1.59; cheaper at Home Depot, no doubt.

8. Some of the kits mentioned above do not include some ABSOLUTELY ESSENTIAL PARTS, available lots of places: These are the two lower and one upper bearing bolts. I read multiple instructions that you MUST replace these bolts and their seals. I got mine at ECS Tuning.

9. The crankshaft seal. I read that the Mini OEM is the worst of three available brands and it's twice as costly. I ordered the one from Conteco or Corteco, and then the one from Feltpro, each about $10-$12. One guy said the Feltpro works best.

10. Plan to remove your oil pan and clean it thoroughly, and also inspect the oil uptake screen and all around the underside of the engine if ANYTHING is broken off the guides or if there is any metal shear anywhere. Do it anyway. Adds hours and grunting to the job, but adding hours beats the alternative.

11. I read that Mini now recommends Permatex Ultra Black instead of an oil pan gasket. Actually, it recommends another brand, which costs more, but Ultra Black is the stuff to get.

12. One of the breather pipes you take out during this job should be inspected inside for oil. If there's oil, your turbo may be leaking oil. That is one of the famous Mini Cooper oil leaks. Others include the oil filter housing gasket, the oil cooler housing gasket, the crankcase seal you have to replace, and the valve cover gasket. So you should get all those done while you're there and all greasy.

1. This can be a DIY job for a LOT less money than taking it to the dealer, but watch the best video first. It's three hours long. Stop and take notes on tools and parts. After this video, the job itself is probably six to 10 if you work fast.

2. The parts come in a kit: chain, tensioner, new guides. You should also buy the bottom sprocket and MAYBE the upper ones, if there is significant damage. And see below on other vital parts which are in some kits but not others.

3. The man who did the long video:

4. He also found that the chain had jumped, throwing the car out of timing. You will read practically EVERYWHERE that once the timing goes, there is no simply DIY way to get it back. Wrong. Watch his amazingly simple method on the video.

5. He paid $120 for the camshaft locking special tool, used. I got a new one for $56 on ebay.

6. If you don't have or don't want to buy the special BMW/Mini thin-walled 14mm long 12-point spark plug socket, use a six-point 15 mm and then a claw grabber to reach down and fish out and re-install, the spark plugs. The torque is low, so you're not going to hurt the plugs with the wrong width socket. You need the grabber anyway if you've ever dropped a nut or bolt.

7. Another expensive tool is the Mini tool to press the crankshaft seal (which you MUST replace) back in. He used a more generic crankshaft seal presser. I found a posting which says you can use the female coupling for a 2" PVC pipe (not the pipe itself, which is too small in diameter) plus a block of wood and a hammer to tap it in. The coupling cost me $1.59; cheaper at Home Depot, no doubt.

8. Some of the kits mentioned above do not include some ABSOLUTELY ESSENTIAL PARTS, available lots of places: These are the two lower and one upper bearing bolts. I read multiple instructions that you MUST replace these bolts and their seals. I got mine at ECS Tuning.

9. The crankshaft seal. I read that the Mini OEM is the worst of three available brands and it's twice as costly. I ordered the one from Conteco or Corteco, and then the one from Feltpro, each about $10-$12. One guy said the Feltpro works best.

10. Plan to remove your oil pan and clean it thoroughly, and also inspect the oil uptake screen and all around the underside of the engine if ANYTHING is broken off the guides or if there is any metal shear anywhere. Do it anyway. Adds hours and grunting to the job, but adding hours beats the alternative.

11. I read that Mini now recommends Permatex Ultra Black instead of an oil pan gasket. Actually, it recommends another brand, which costs more, but Ultra Black is the stuff to get.

12. One of the breather pipes you take out during this job should be inspected inside for oil. If there's oil, your turbo may be leaking oil. That is one of the famous Mini Cooper oil leaks. Others include the oil filter housing gasket, the oil cooler housing gasket, the crankcase seal you have to replace, and the valve cover gasket. So you should get all those done while you're there and all greasy.

#43

Thanks for the order. Yea to do the turbo oil lines and the oil filter main housing gasket are easier when you are there anyway.

__________________

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

#44

I went to Partsgeek.com first. I had a question. There was no number to call at the web site. They make you fill out an email form, so I did, with the question in complete detail, needing a yes or no answer. I got back an email that didn't answer the question. It said "Call this number..." No.

#45

N12 non-turbo differences

Anybody replace the timing chain set on the non-turbo N12 engine?

i bought an overheated 2009 Clubman for cheap and brought it back to life with a new water pump, pipe, and thermostat housing. 107,000 miles.

Oil leaking from valve cover gasket, so I decided to replace it. Car ran fine and hesitated a little when pulling out from a stop. No noises or rattles. Two oil changes and no metal shavings or flakes in oil in 4,000 miles. 112,000 miles.

Put valve cover back on and got a p0012 code and cc-id 031 after a few days.

Ordered Timing kit $200 and tool kit $42. Looks straight forward to change.

#46

The reason why you dont see a lot of DYI on this is that you pretty much need two different special tools to complete this job. One is a camshaft holder tool that garuntees your cams on in the perfect spot since these engine are interference motors. and the second tool is a flywheel locker. This is strongly suggested that you dont attempt yourself. I am in the fight with mini getting mine replaced under warranty but i know that my local dealer in oklahoma has quoted me 1700 for job and i found another local shop that shot me 1200

#47

We do also have our timing chain replacement live on our site as well here: http://www.pelicanparts.com/techarti...eplacement.htm. We have links to the engine tools from the article in the body as well, for those who want them.

__________________

Your Trusted Source For DIY and Parts

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

#48

For anyone buying the eBay tools, be aware of the crankshaft pin. The handle is tack welded. It broke off with very little effort. I drilled a hole and had an Allen wrench welded on it to replace the soft metal handle. Also, the pin hole on the transmission can be cleaned out with a 1/2" plumbers wire brush. These are the ones that plumbers use when cleaning copper pipe fittings before soldering them. I also had to sand the pin down slightly to get it to fit in the hole. Tolerance and quality are not the best with the Chinese tool.

Last edited by Tim McCreary; 03-18-2017 at 01:13 AM. Reason: clarify info

#49

Installed the new chain and guides. I'm getting ready to torque down the bolts. My cheapo manual states nothing about the timing marks on the cam in relation to the camshaft. I assume it does not matter. Can anyone confirm?

Also with the N12, the crankshaft torque changed from 50Nm+100• to 50Nm+180•. Can anyone confirm?

Also with the N12, the crankshaft torque changed from 50Nm+100• to 50Nm+180•. Can anyone confirm?

#50