How To Slightly new take on the Belt Removal tool DIY

#1

Slightly new take on the Belt Removal tool DIY

A little while ago I went looking for directions on how to replace the serpinitne belt on my R53. Naturaly, I would up here. while reading down many workarounds to avoid purchasing the belt tension tool, I found that this write up was the best with the best photos:

https://www.northamericanmotoring.co...tine-belt.html

After reading that post, I was ready to tackle it but a bit leary of the "Scary factor" when prying on the tensioner. I would like to add a very simple and cheap way to do this by adding to gerldoc's DIY and eliminating the need to fabricate a tool.

All you will need is a 5.5mm allen wrench, a water weenie, 16mm socket, length of wire and a metal pipe or anything else to work as a pry bar yet thin enough for this application.

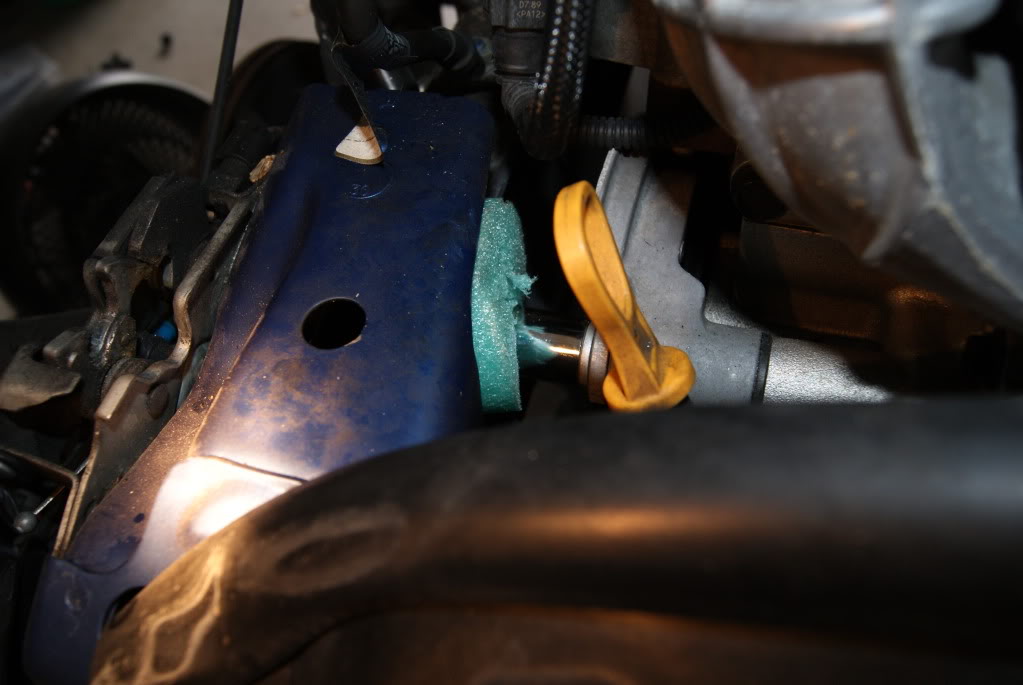

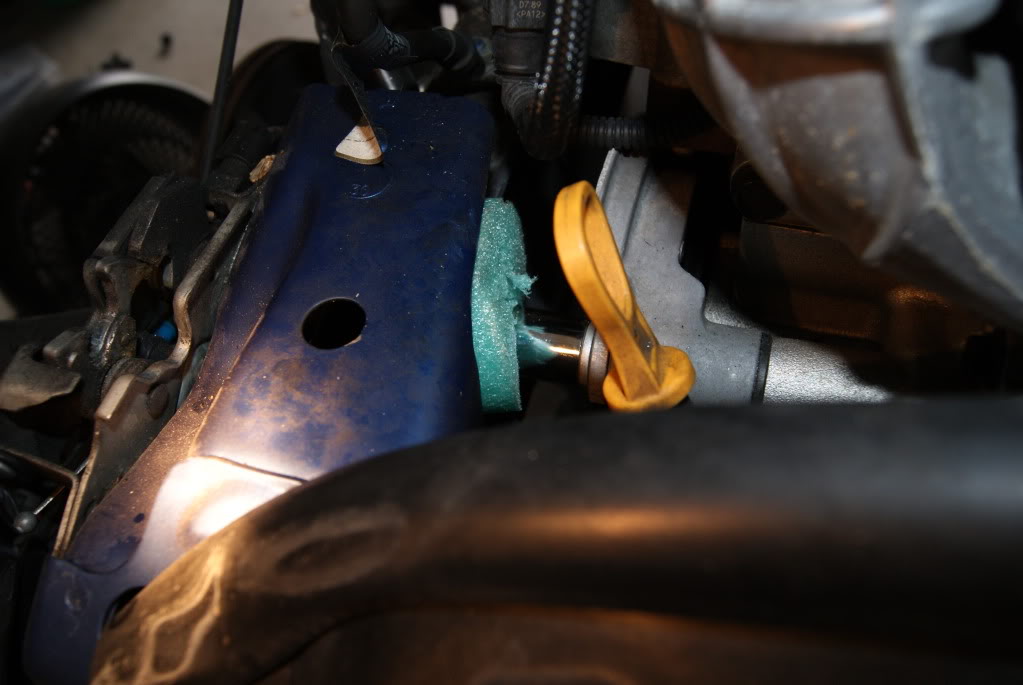

Ok, the first thing I did was cut a small section off of the water weenie ($1 at the dollar store). ::My pictures will not be as clear as gurldoc's)

The width of foam I used was actually less than that in the picture. For $1, you get alot of foam to get the right size by trial and error. This foam is to place between the 16mm socket that acts as a fulcrum and the side of the engine bay. This keeps the socket firm on the bolt and is soft against the metal of the car.

Next, take a 5.5mm (Or whatever SAE sive fits snug) allen wrench and put the short end into the far hole on the belt tensioner.

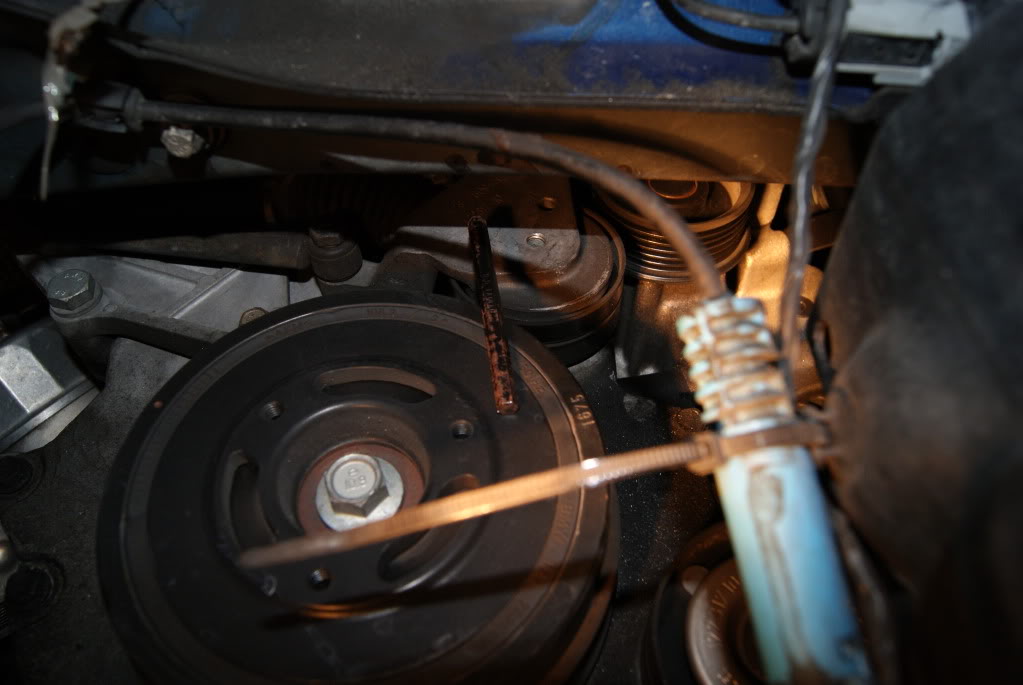

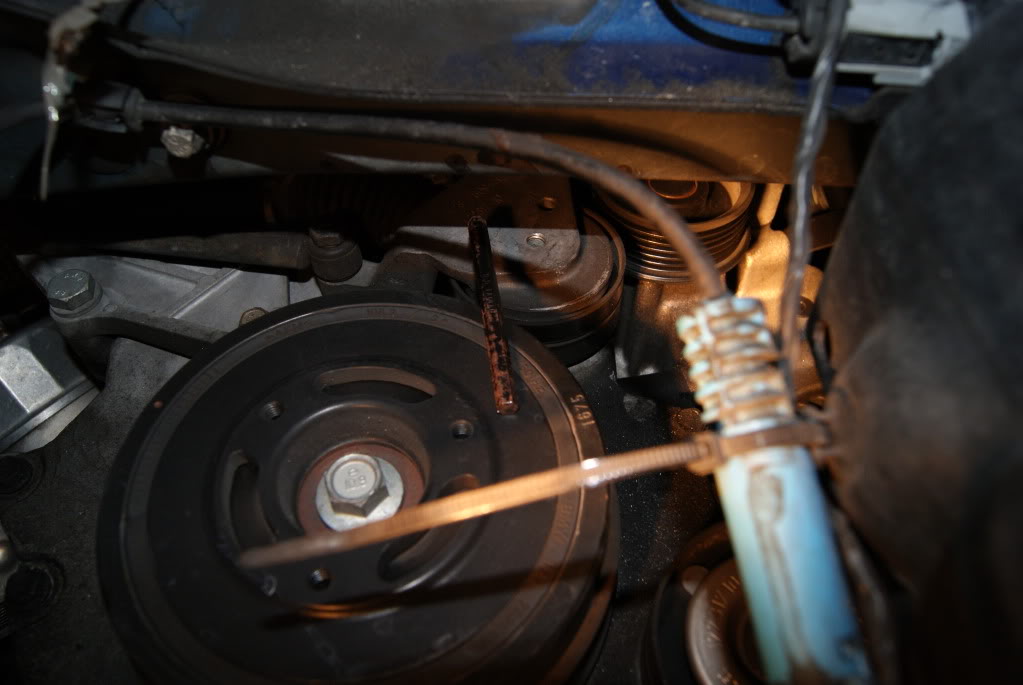

Then, you insert your prybar from the top of the engine down, over the 16mm scoect fulcrum and under the allen wrench. I used the pump handle from my jack. A good length of pipe would be great as well. It just has to fit between the tensioner and the long section of the allen wrench without pulling the short section out of the tensioner too much.

In the second pic above, you can see the bar hooked under the allen wrench.

Next, just pull down on the prybar and stick the metal wire in the hole as it is revealed once the tensioner is compressed. (See gurldoc's link for details) For the wire, I used the metal wire from a cheap holloween lawn decoration. If your prybar is not very long like mine, you will probably want to have someone help you to put the metal wire in the hole.

That's it. It was VERY easy and safe. And cheap too when compared to buying the tool. I was only out $1 as I had the other bits in the garage.

https://www.northamericanmotoring.co...tine-belt.html

After reading that post, I was ready to tackle it but a bit leary of the "Scary factor" when prying on the tensioner. I would like to add a very simple and cheap way to do this by adding to gerldoc's DIY and eliminating the need to fabricate a tool.

All you will need is a 5.5mm allen wrench, a water weenie, 16mm socket, length of wire and a metal pipe or anything else to work as a pry bar yet thin enough for this application.

Ok, the first thing I did was cut a small section off of the water weenie ($1 at the dollar store). ::My pictures will not be as clear as gurldoc's)

The width of foam I used was actually less than that in the picture. For $1, you get alot of foam to get the right size by trial and error. This foam is to place between the 16mm socket that acts as a fulcrum and the side of the engine bay. This keeps the socket firm on the bolt and is soft against the metal of the car.

Next, take a 5.5mm (Or whatever SAE sive fits snug) allen wrench and put the short end into the far hole on the belt tensioner.

Then, you insert your prybar from the top of the engine down, over the 16mm scoect fulcrum and under the allen wrench. I used the pump handle from my jack. A good length of pipe would be great as well. It just has to fit between the tensioner and the long section of the allen wrench without pulling the short section out of the tensioner too much.

In the second pic above, you can see the bar hooked under the allen wrench.

Next, just pull down on the prybar and stick the metal wire in the hole as it is revealed once the tensioner is compressed. (See gurldoc's link for details) For the wire, I used the metal wire from a cheap holloween lawn decoration. If your prybar is not very long like mine, you will probably want to have someone help you to put the metal wire in the hole.

That's it. It was VERY easy and safe. And cheap too when compared to buying the tool. I was only out $1 as I had the other bits in the garage.

#2

I know I'm resurrecting an old thread, but I wanted to say thank-you for this post. I picked up a used '05 MCS in Austin, TX this past Saturday and immediately started driving it home to Charlotte, NC. When I was almost to Mississippi, when things went wrong and I recognized the symptoms (CEL, AC went warm, thermostat climbing rapidly) from when I previously owned an R53. I quickly coasted off the highway (I happened to be right an an exit) and into a nearby parking lot. There I was at 10pm in a nearly abandoned parking lot of an off-track betting place in rural Louisiana, looking down at a broken belt with no spares in the car and just a few tools (I picked up some slime, oil allen/star wrenches and a compressor right after buying the car for the drive home). I was several hundred miles from the nearest MINI dealer on a Sunday morning and 400+ miles from home. Crap!

Amazingly I found a parts store with a belt at 8:30 the next morning. It was only a mile or so from the hotel I found the night before, so off I went for my morning walk. I got a belt, some coolant, a tool set in a blow-molded case, the biggest pry bar they had and a 16mm socket. Once I got the car apart and started to replace the belt, I found that the idler pulley was moving strangely... the bearing had siezed and that is why the belt broke. :( Luckily, thanks to the internet, I found a parts shop about 20 minutes away that had a pulley on the shelf (looked pretty generic plastic and cheap, but any port in a storm) and I paid a taxi driver to pick it up and drive it to me.

NOTE: I didn't have the foam with me out on the side of the road and I had a frustrating hour trying to compress the tensioner spring with my short pry bar. The socket would slip off of the bolt once I put much tension on it (probably why you put the foam there) and my attempts to recreate the foam effect with other things (owners manual, wrenches, etc) didn't work. I FOUND SOMETHING THAT WORKED PERFECTLY, THOUGH.... LOOSENING THE FULCRUM BOLT 3-4 TURNS! That moves the bolt out about 1/2 cm, so the socket sits out closer to the engine compartment wall and holds much better. Once I did that, I got the tensioner pinned back on my first try (after 50+ unsuccessful tries the previous hour).

Amazingly I found a parts store with a belt at 8:30 the next morning. It was only a mile or so from the hotel I found the night before, so off I went for my morning walk. I got a belt, some coolant, a tool set in a blow-molded case, the biggest pry bar they had and a 16mm socket. Once I got the car apart and started to replace the belt, I found that the idler pulley was moving strangely... the bearing had siezed and that is why the belt broke. :( Luckily, thanks to the internet, I found a parts shop about 20 minutes away that had a pulley on the shelf (looked pretty generic plastic and cheap, but any port in a storm) and I paid a taxi driver to pick it up and drive it to me.

NOTE: I didn't have the foam with me out on the side of the road and I had a frustrating hour trying to compress the tensioner spring with my short pry bar. The socket would slip off of the bolt once I put much tension on it (probably why you put the foam there) and my attempts to recreate the foam effect with other things (owners manual, wrenches, etc) didn't work. I FOUND SOMETHING THAT WORKED PERFECTLY, THOUGH.... LOOSENING THE FULCRUM BOLT 3-4 TURNS! That moves the bolt out about 1/2 cm, so the socket sits out closer to the engine compartment wall and holds much better. Once I did that, I got the tensioner pinned back on my first try (after 50+ unsuccessful tries the previous hour).

The following users liked this post:

MiniBeemer (08-15-2022)

#3

if there is a will, there is a way

Good to see your tenacity in getting the job done by hook or by crook. Nowadays we tend to just go buy something instead of spending a bit more effort and time trying to solve a problem with limited means - in the name of time and money. Very often, in a pinch, I try to be resourceful. A trip to the store, or worst waiting for the damned thing to arrive from e-commerce I can often get it done faster if I try a bit harder to work with what I already have.

The R53 belt tensioner is quite hard to compress with improvised tool so my salute to you.

The R53 belt tensioner is quite hard to compress with improvised tool so my salute to you.

#4

Yeah... but I'm all about the "Use the right tool for the right job" thing as well. I've got a shiny new tensioner tool on the way from Aaron at Outmotoring right now. I love ingenuity, but when I'm sweating my **** off in a parking lot, trying to fix that stupid pulley and belt, I would have paid double for the right tool! :D

If this were a tool that I'd only use once, I'd probably skip it. I tend to hang out with other MINI folks at large events where people tend to drive a bit harder than usual, making my collection of tools and spare parts quite handy to have.

I can still remember being at the Spaghetti Supper at MOTD back in 2009 or so. I saw Nathan across the crowd (he's the owner of another national MINI site that will probably turn to **** if I type it here on NAM). I usually wouldn't have noticed so much, except he was talking w/ another guy and pointing animatedly in my direction. When we made eye contact he waved me over. Turns out that the guy limped into Fontana with an R53 with a clutch problem.... the slave cylinder was shot, leaking like crazy and only getting worse. I had a thing for that part dying (I replaced it almost every other year) and carried a spare in the boot at all times, along with the block of wood I had specifically shaped to compress the piston for bleeding of the system. The poor guy had made the rounds to all of the vendors and nobody had a spare. I handed him the part, he mailed me a check for the $50 the following week and I saw him out on the Dragon the following morning. :D

If this were a tool that I'd only use once, I'd probably skip it. I tend to hang out with other MINI folks at large events where people tend to drive a bit harder than usual, making my collection of tools and spare parts quite handy to have.

I can still remember being at the Spaghetti Supper at MOTD back in 2009 or so. I saw Nathan across the crowd (he's the owner of another national MINI site that will probably turn to **** if I type it here on NAM). I usually wouldn't have noticed so much, except he was talking w/ another guy and pointing animatedly in my direction. When we made eye contact he waved me over. Turns out that the guy limped into Fontana with an R53 with a clutch problem.... the slave cylinder was shot, leaking like crazy and only getting worse. I had a thing for that part dying (I replaced it almost every other year) and carried a spare in the boot at all times, along with the block of wood I had specifically shaped to compress the piston for bleeding of the system. The poor guy had made the rounds to all of the vendors and nobody had a spare. I handed him the part, he mailed me a check for the $50 the following week and I saw him out on the Dragon the following morning. :D

The following users liked this post:

MiniBeemer (08-15-2022)

Thread

Thread Starter

Forum

Replies

Last Post

Kimolaoha

R56 :: Hatch Talk (2007+)

70

07-05-2023 01:04 PM

Mini Mania

Drivetrain Products

0

08-21-2015 11:25 AM

minipopkart

R50/R53 :: Hatch Talk (2002-2006)

2

08-13-2015 05:22 AM